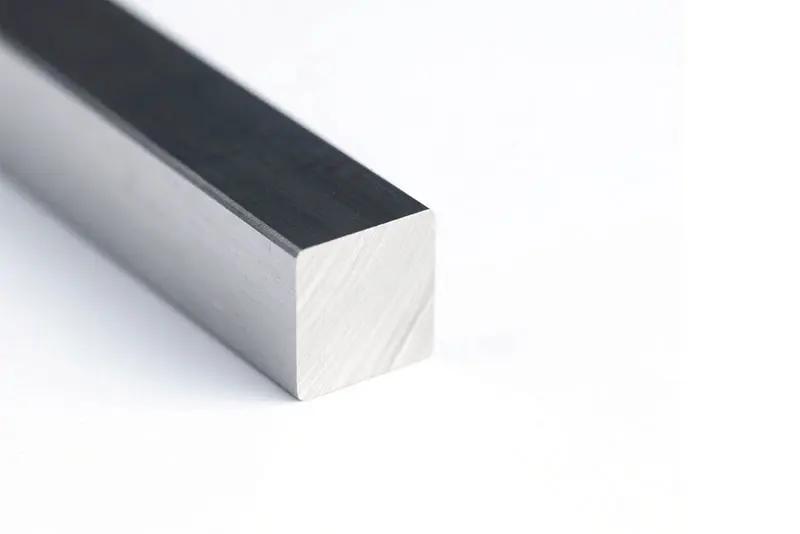

Ti6Al4V Titanium Alloy Rectangular Bar High Strength Corrosion Resistant

Category

Minerals & Metallurgy

Sub-Category

Titanium

Completed orders

0

Price

$10.00

Delivery Cost

$1.00

Minimum Order

1

Kilogram(Weight)

Location

19th Wenquan Industrial Park,Titanium City Road, High-tech District, Baoji City, Shaanxi Province, China, , ,

Product name:Titanium square rod

Length:Max.6000

Technique:Rolled

Brand Name:Yesheng

Shape:Square

Processing Service:Bending, Welding, Decoiling, Cutting, Punching

Material:Titanium Gr1gr2 Gr5 Gr9 Gr10 Gr12

Surface:Polished

Advantage:Corrosion Resistance

Application: Metallurgy, electronics, medical, chemical, petroleum, etc.

Payment terms: T/T (30%DEPOSIT)

Packing: Export packing

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

High Purity Polishing and Cutting Titanium Wire

Price: $10.00 per piece

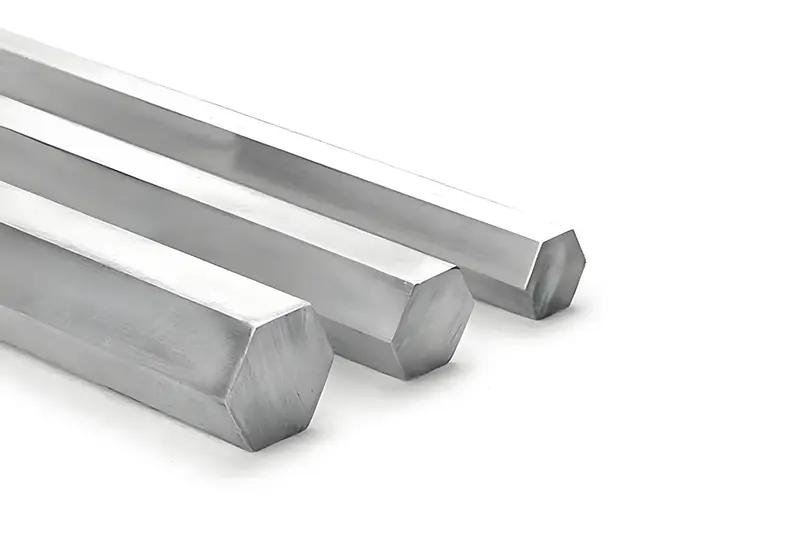

High Purity Titanium Hex Rod for Industry

Price: $10.00 per piece

High Strength Low Density Titanium Round Bar Ø4mm x 250mm

Price: $10.00 per piece