High Purity Polishing and Cutting Titanium Wire

Category

Minerals & Metallurgy

Sub-Category

Titanium

Completed orders

0

Price

$10.00

Delivery Cost

$1.00

Minimum Order

1

Kilogram(Weight)

Location

19th Wenquan Industrial Park,Titanium City Road, High-tech District, Baoji City, Shaanxi Province, China, , ,

Product Name: Titanium Wire

Ti (Min):99.6%

Place of Origin: Shaanxi, China

Processing Service: Welding, Cutting

Strength:895MPa

Wire Gauge: Custom

Surface: Pickling Polished

Standard: ASTM B863 AWS A5.16

Shape: Spool Coil Straight

Strength:895MPa

Application: industrial

MOQ: Negotiable for Bulk Orders

Packing: According to Client's Needs (Wooden box/ Carton / Pallet)

Sample: Available

Delivery Time: 3–30 Days

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Ti6Al4V Titanium Alloy Rectangular Bar High Strength Corrosion Resistant

Price: $10.00 per piece

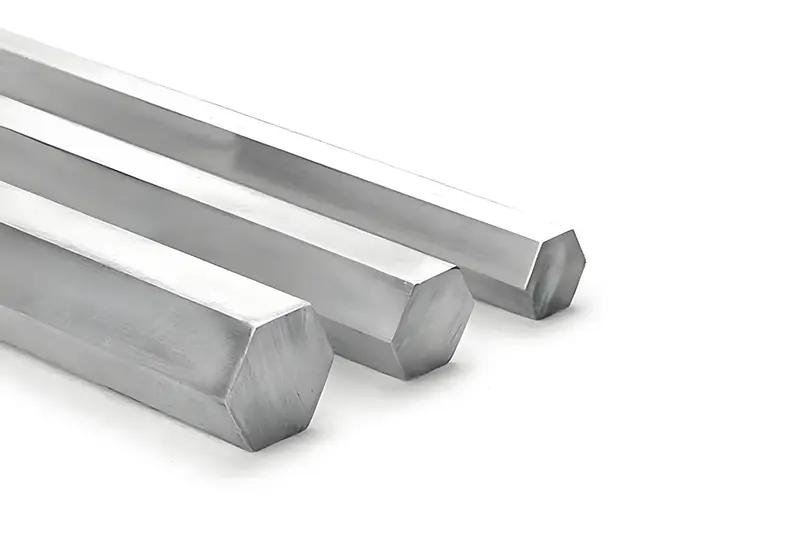

High Purity Titanium Hex Rod for Industry

Price: $10.00 per piece

High Strength Low Density Titanium Round Bar Ø4mm x 250mm

Price: $10.00 per piece