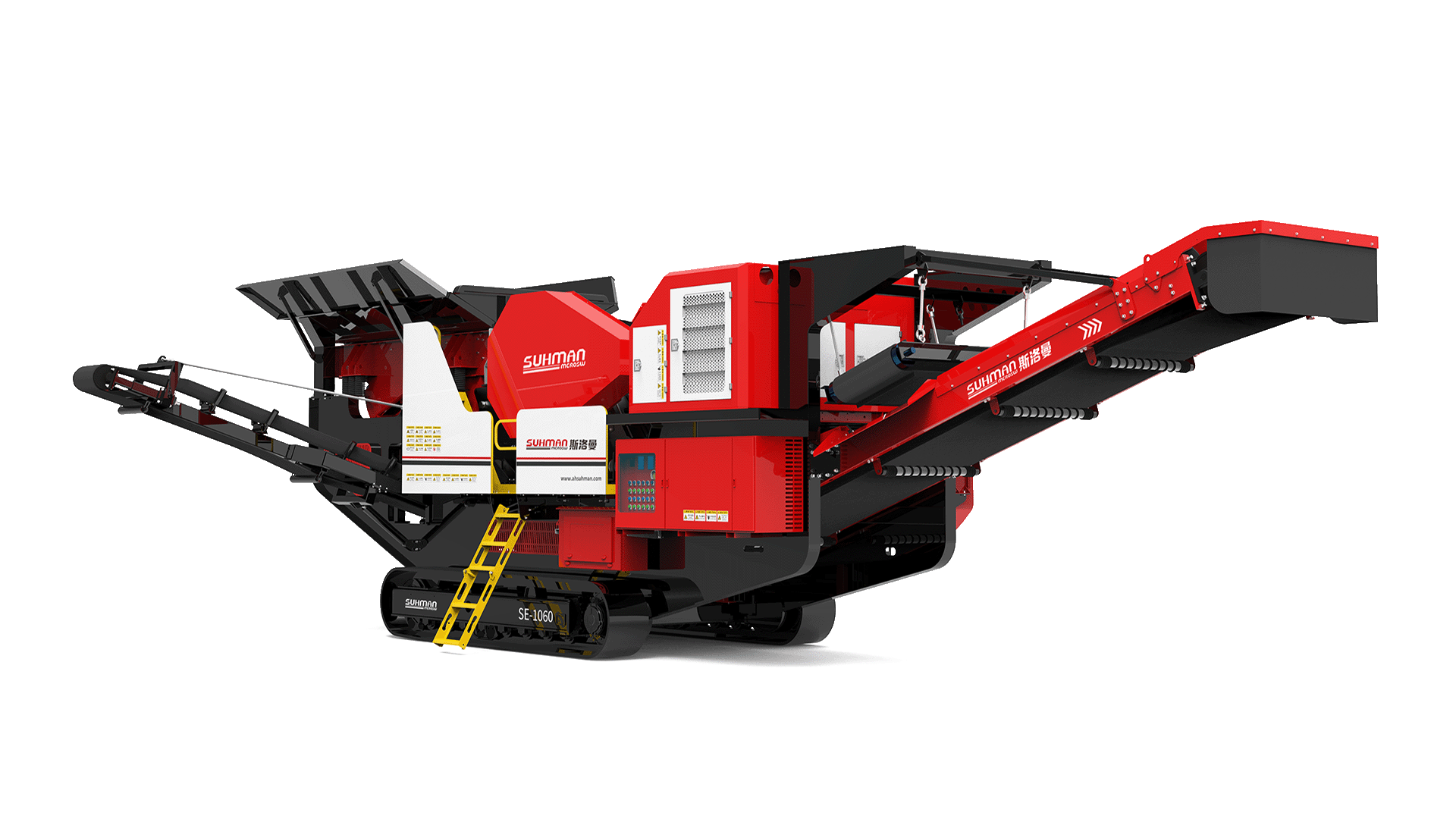

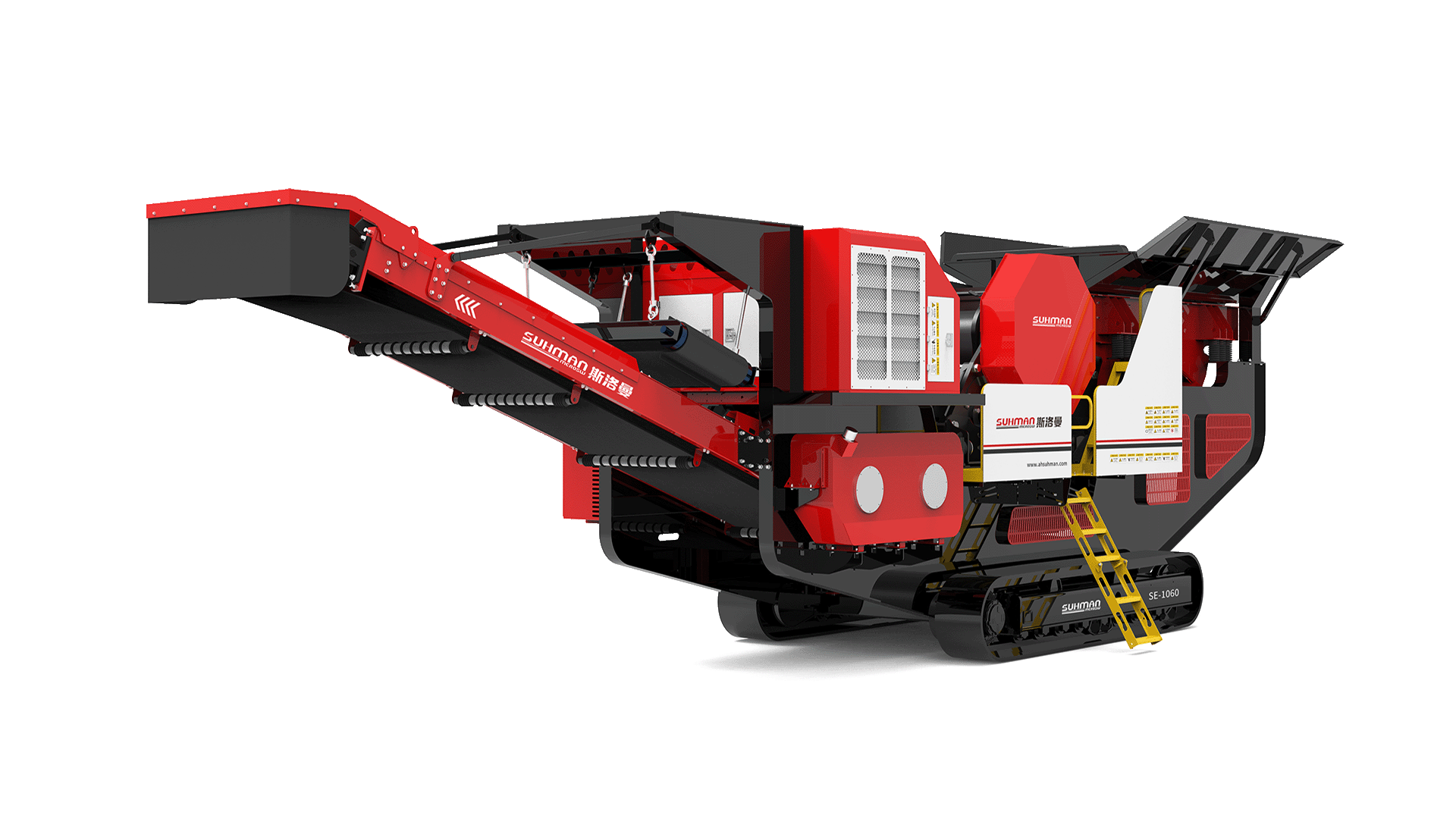

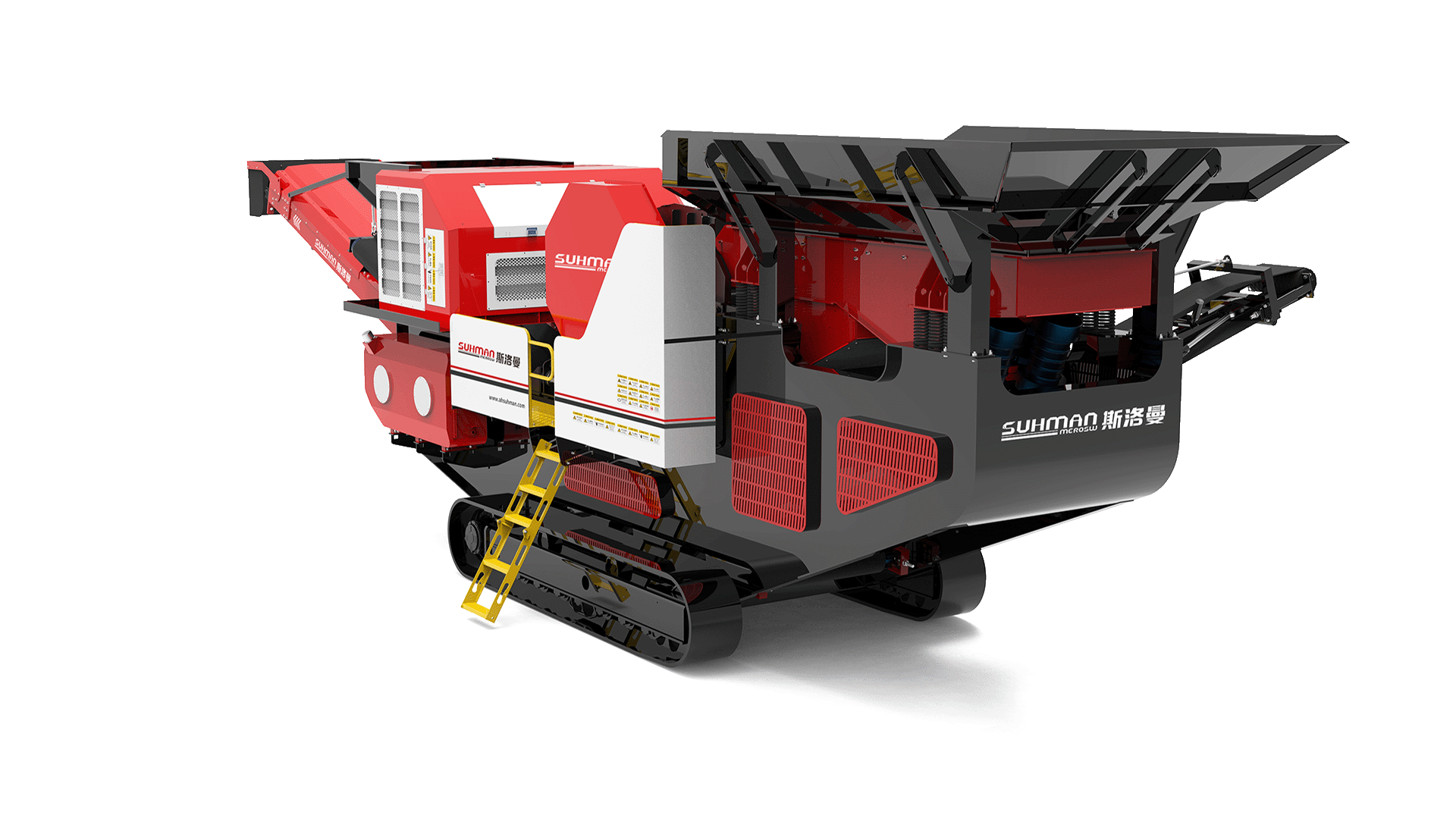

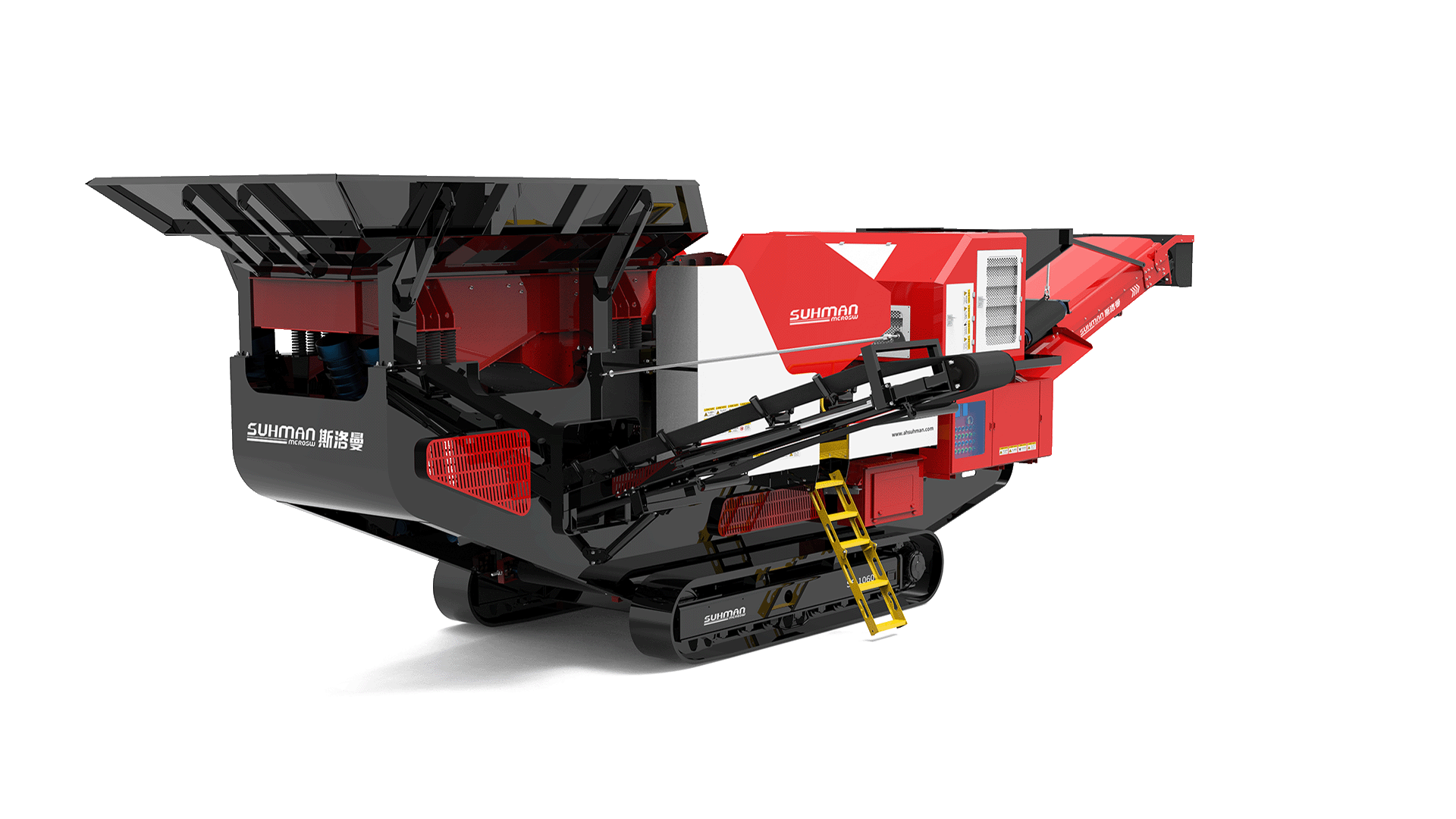

SE-1060 Mobile Jaw Crusher

Category

Machinery

Sub-Category

Mining Machinery

Completed orders

0

Price

$25000.00

Delivery Cost

$10000.00

Minimum Order

1

pieces

Location

No.43 Tangkou Road, Economic Development Zone, Feixi County, , ,

SE-1060 tracked jaw crusher is engineered for primary crushing in demanding applications. It performs effectively across a wide range of materials including soft rock, construction waste, concrete blocks, and hard rock. Its tracked design allows it to navigate complex terrain, making it especially suitable for mobile operations in mining sites, urban demolition zones, road and bridge construction, and aggregate production yards.

Thanks to its mobility and quick setup capabilities, the SE-1060 jaw crusher reduces the need for fixed infrastructure, shortens project timelines, and lowers transportation costs of raw materials. Its compact design and high crushing capacity also make it ideal for use in space-constrained environments without compromising performance.

Product Parameter

| Project | Name | SE-1060 |

| Feeding equipment | Feeding capacity (t/h) | 200-250 |

| Maximum feeding size (mm) | 4000×1100 | |

| Feeding height (mm) | 3600 | |

| Hopper volume (m ³) | 3 | |

| Vibrating Feeder | Length x Width (mm) | 4000×1100 |

| Motor model | PJMV-65-6 | |

| Power (KW) | 4.5×2 | |

| crusher | Jaw crusher | 1060 |

| Crusher feed inlet length x width (mm) | 1060×750 | |

| Maximum feed particle size (mm) | 700 | |

| Crusher weight (t) | 18 | |

| Adjustment range of discharge port | 80-180 | |

| Main engine bearing model | 23060 | |

| Main breaking motor model | YE3-315L-6 | |

| Crusher power (KW) | 110 | |

| Main belt | Stacking height (mm) | 3000 |

| Length x Width (mm) | 9500×1350 | |

| Electric roller model | M1-270 | |

| Power (KW) | 9.2×2 | |

| Tail belt | Stacking height (mm) | 2350 |

| Width (mm) | 880 | |

| Electric roller model | M1-270 | |

| Power (KW) | 5.5 | |

| De-ironing separator | Length x Width (mm) | 2100×910 |

| Power (KW) | 3 | |

| Complete machine | Engine power (KW) | 100 |

| Track chassis model | LDZ55-3657 | |

| Whole machine weight (t) | 44t | |

| Processing capacity of crusher (t/h) | 200-250 | |

| Total power of crushing operation (KW) | 139.4 | |

| Working dimensions (length, width, height/mm) | 15500×4150×3900 | |

| Transportation dimensions (length, width, height/mm) | 14850×3100×3900 |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

SS-7018 Mobile Inclined Vibrating Screening Plant

Price: $25000.00 per piece

SF-580D Heavy Duty Mobile Impact Crusher

Price: $25000.00 per piece

SE-650D Mini Mobile Jaw Crusher

Price: $25000.00 per piece

SF-380D Mobile Impact Crusher

Price: $25000.00 per piece