SF-580D Heavy Duty Mobile Impact Crusher

Category

Sub-Category

Completed orders

Price

Delivery Cost

Minimum Order

Location

Engineered for demanding and high-load crushing tasks, the SF-580D is well-suited for projects that require large feed sizes, high throughput, and stable performance. It is commonly used in the following applications:

Construction Waste Recycling on a Large Scale

SF-580D Heavy Duty Mobile Impact Crusher excels at processing mixed demolition waste such as reinforced concrete, bricks, and debris. It helps convert waste into valuable recycled aggregate directly on-site, minimizing the need for transport and supporting circular construction practices.Urban Demolition and Infrastructure Removal

Ideal for the dismantling of bridges, highways, factories, and other urban infrastructure, the unit allows fast on-site crushing and quick relocation to the next job site, significantly reducing project downtime.Quarry and Aggregate Production Support

It can be deployed as a primary or secondary crusher in stone quarries, efficiently processing materials like limestone, basalt, or granite to produce high-quality aggregates for construction use.Heavy-Duty and Time-Sensitive Projects

For contractors needing fast setup, continuous operation, and minimal maintenance interruption, SF-580D offers reliable performance and user-friendly operation, making it a valuable solution for tight-schedule or remote projects.

With its robust structure, strong crushing capability, and intelligent control system, SF-580D stands out as a reliable choice for contractors and recycling companies. Optional configurations such as an overband magnet, dust suppression system, or remote control operation can further enhance safety, efficiency, and environmental compliance on site.

Product Parameter

| Project | Name | SF-580D |

| Feed section | Feeding capacity (t/h) | 300 |

| Hopper volume (m³) | 6 | |

| Power (kw) | 4.5×2 | |

| Feeder size (length x width) (mm) | 3950×1460 | |

| Feeding height (mm) | 3850 | |

| Crusher | Crusher model | 1315 |

| Feed inlet size (length x width) (mm) | 1540×1100 | |

| Maximum feed particle size (mm) | <700 | |

| Adjustment range of discharge port (mm) | 300-500\0-150 | |

| Crusher weight (t) | 23 | |

| Crusher power (kw) | 315 | |

| Main belt | Length x Width (mm) | 11300×1600 |

| Unloading height (mm) | 3250 | |

| Power (kw) | 9.5×2 | |

| Belt for finished materials | Length x Width (mm) | 5200×1350 |

| Unloading height (mm) | 2860 | |

| Power (kw) | 7.2×2 | |

| Return material hanging sieve | Length x Width (mm) | 4600×2160 |

| Power (kw) | 3.7×2 | |

| Number of sieve layers (layers) | 1 | |

| Screen size (mm) | 4000×1540 | |

| Transition belt | Length x Width (mm) | 1750×970 |

| Power (kw) | 3 | |

| Return conveyer belt | Length x Width (mm) | 7200×970 |

| Power (kw) | 5.5 | |

| De-ironing separator | Length x Width (mm) | 2100×910 |

| Power (kw) | 3 | |

| Complete machine | Track chassis model | LDZ55-3657 |

| Engine power (kw) | 100 | |

| Whole machine weight (t) | 53 | |

| Machine processing capacity (t/h) | 180-230 | |

| Total power of crushing work (kw) | 378.1 | |

| Working dimensions (length, width, height/mm) | 15932×3700×4100 | |

| Transportation dimensions (length, width, height/mm) | 15932×3500×3900 |

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

SC-85D Mobile VSI Sand Making Machine

SZ-450D Mobile Heavy Duty Screening Plant

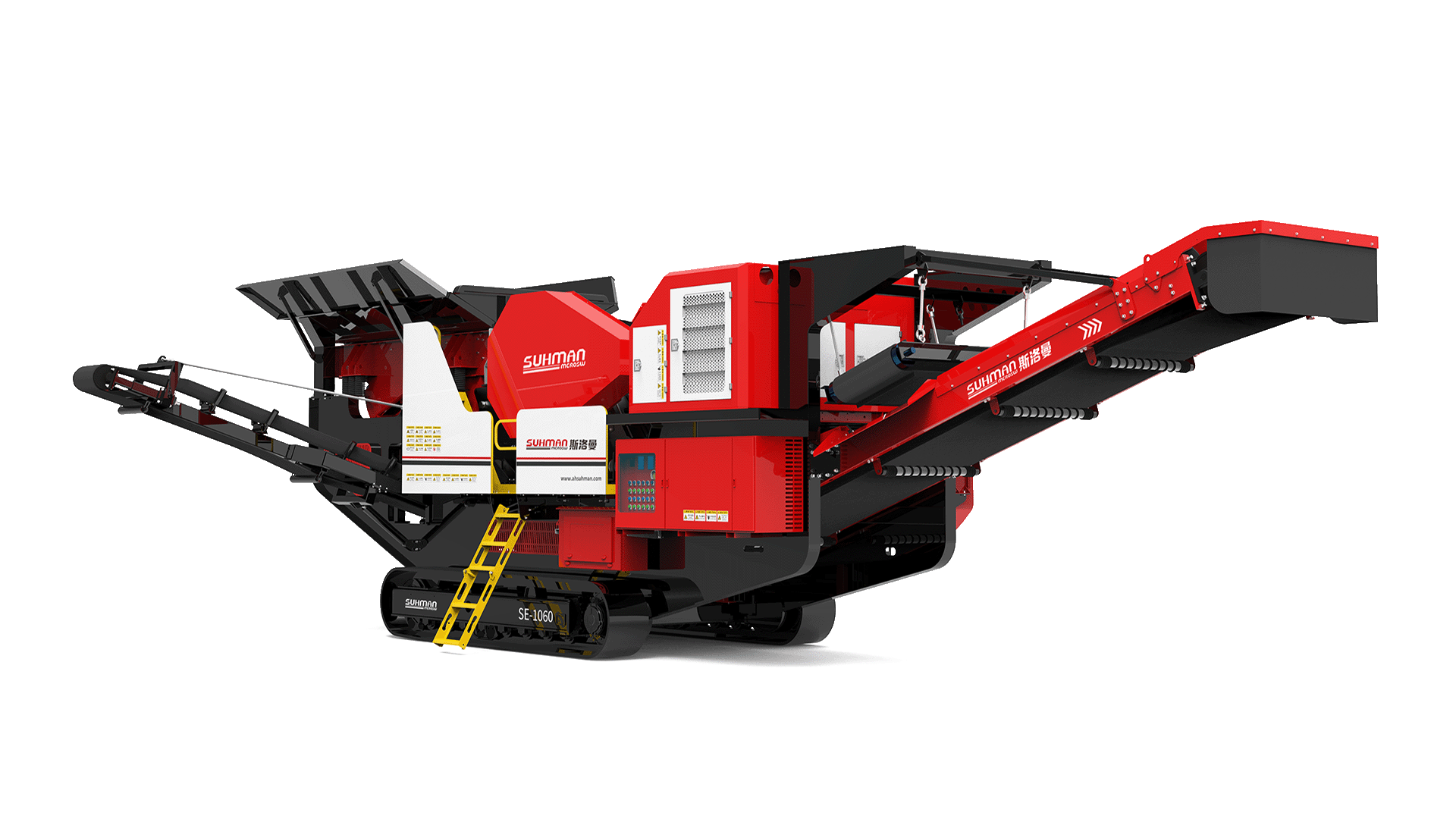

SE-1060 Mobile Jaw Crusher