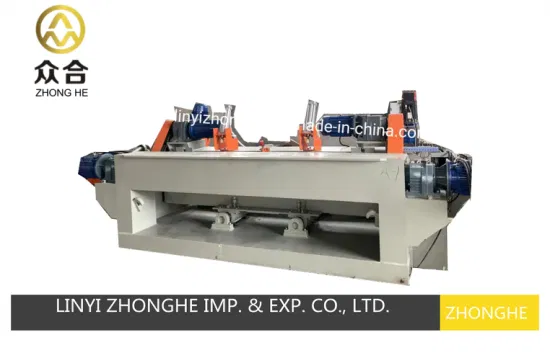

Plywood Machinery Type Automatic Veneer Dryer with Automatic Loader B2B Factory Pricing Supplier

Category

Machinery

Sub-Category

Other Machinery & Industry Equipment

Completed orders

0

Price

$165000.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

| Model NO. | BG1333-13+2 |

| Type | Dryer |

| Automatic | Semi-Automatic |

| Certification | CE, ISO |

| Machine Use | Drying Wood Veneer |

| Machine Clour | According to Client Needs |

| Machine Power | 179.5 Kw |

| Shipment | 3*40hc |

| Transport Package | Plywood |

| Specification | BG1333-13+2 |

| Trademark | ZHONGHE |

| Origin | China |

| HS Code | 8419320000 |

| Production Capacity | 1 Set/Month |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Fast and Precise Wood Veneer Peeling Machine Affordable Factory Pricing Partners

Price: $18000.00 per piece

Spindle Less Wood Veneer Peeling Machine with Guillotine China Wholesale Factory

Price: $18000.00 per piece

Veneer Working Glue Spreader Plywood Machine Made in China Global Wholesale Market Operations

Price: $10600.00 per piece

High Speed Veneer Peeling Machine Wood Working Machine Industrial Exporter Wholesale

Price: $15900.00 per piece