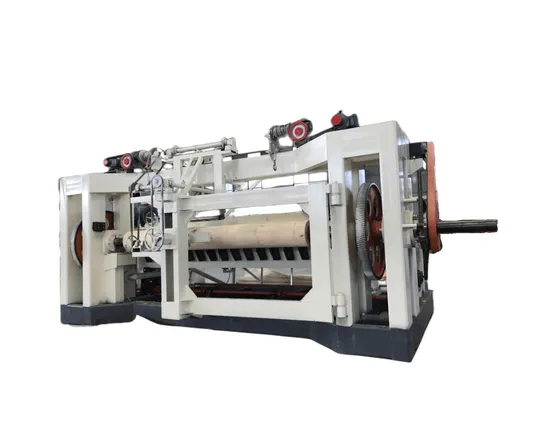

High Quality 4 Feet Spindle Less Veneer Peeling Machine Industrial Wholesale

Category

Machinery

Sub-Category

Other Machinery & Industry Equipment

Completed orders

0

Price

$14500.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

| Model NO. | WXQ1500L-450 |

| Type | Peeling Machine |

| Automatic | Semi-Automatic |

| Certification | ISO |

| Double Roller Diameter | 180 mm |

| Double Roller Reducer | 11 Kw |

| Single Roller Diameter | 180 mm |

| Hydraulic Pump Fan | CF4t-250s |

| Guiding Bar | 2 Pieces |

| Max. Working Diameter | 600 mm |

| Total Motor Power | 22.5 Kw |

| Peeling Knife | 1500*140*12.7 mm |

| Peeling Speed | 45 Meter/Min |

| Machine Weight | 3000 Kgs. |

| Transport Package | Plastic Package |

| Specification | weight: 1150kg |

| Trademark | ODM Service |

| Origin | China |

| HS Code | 8465940000 |

| Production Capacity | 1000pieces/Years |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

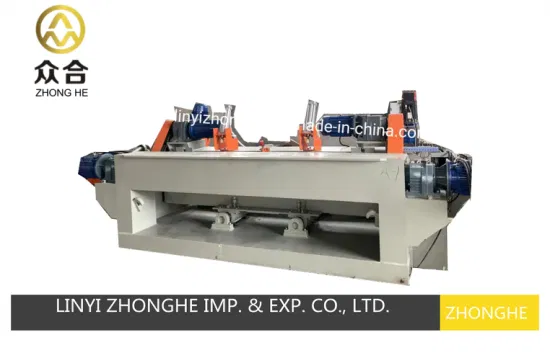

4 Feet Spindle Less Veneer Rotary Peeling Machine China Manufacturing Hub

Price: $18000.00 per piece

Spindle Less Wood Veneer Peeling Machine with Guillotine China Wholesale Factory

Price: $18000.00 per piece

1-10m High Quality Factory Cheap Price Lift Tables Hydraulic Lift Tables Trade Factory Direct

Price: $800.00 per piece

Wood Veneer Peeling Knife Grinder Machine Supplier Wholesale Production

Price: $6900.00 per piece