Waste-plastic-derived Baling Wire

Category

Sub-Category

Completed orders

Price

Delivery Cost

Minimum Order

Location

Introducing Waste-Plastic-Derived Baling Wire, an eco-friendly solution designed to replace traditional steel baling wire. By utilizing recycled plastic, you reduce hidden CO₂ emissions while maintaining operational continuity—same presses, same operators, same bales. Transform your baling process and contribute to a cleaner environment with a different carbon story.

The global shift towards sustainable practices has led to innovative solutions across various industries. One such breakthrough is the Waste-Plastic-Derived Baling Wire, a revolutionary product that offers an environmentally friendly alternative to traditional steel baling wire. This product not only facilitates the binding of bales but also significantly reduces the carbon footprint associated with the baling process.

For every tonne of baling wire shipped out, we uncover an alarming amount of hidden CO₂ emissions associated with the production of virgin steel. The Waste-Plastic-Derived Baling Wire aims to change this narrative by utilizing recycled plastic waste as its primary material.

When bales are constructed using our baling wire, you're not just managing waste materials; you are actively reducing your carbon footprint across your entire outbound logistics. Instead of feeding your balers with virgin steel, which contributes significantly to carbon emissions, you have the opportunity to clean up not only the rescued materials but also the environmental impact of your operations.

The Waste-Plastic-Derived Baling Wire designed to seamlessly fit into existing operations, meaning you will not have to modify your processes. You can continue to use the same presses, employ the same operators, and produce the same bales while embracing a product that tells a different carbon story.

For more details please visit www.kywire.com

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

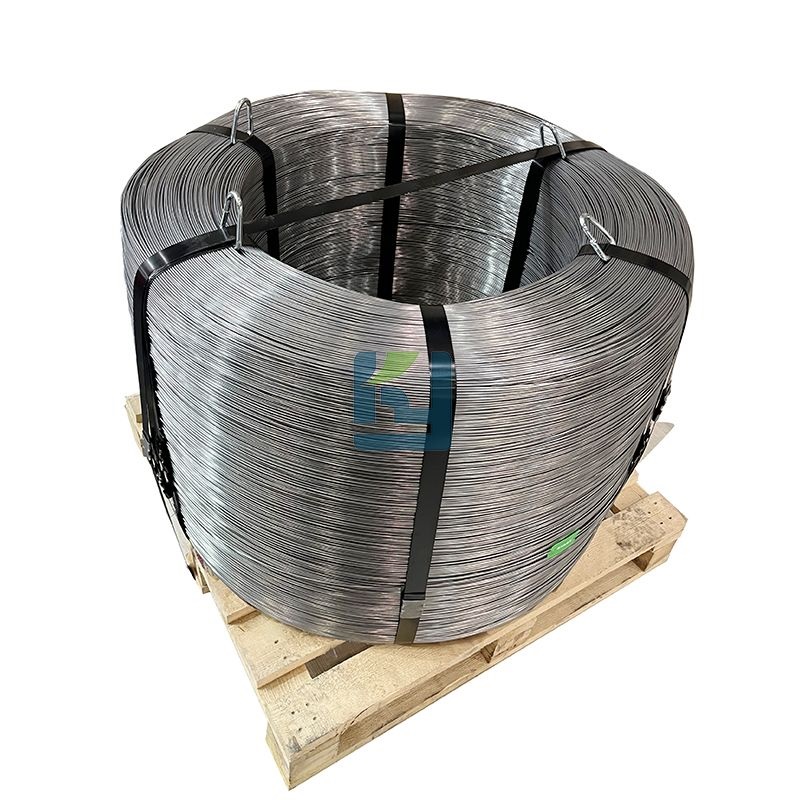

Galvanized Large Coil Baling Wire

Single Loop Bale Ties

12 Gauge Galvanized Hi-Tensile Baling Wire