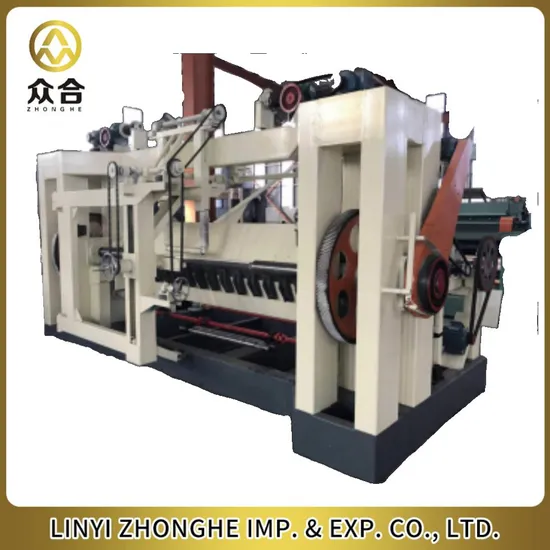

Spindle Less Veneer Peeling Cutting Machine with Guillotine OEM Manufacturer

Category

Machinery

Sub-Category

Other Machinery & Industry Equipment

Completed orders

0

Price

$20000.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

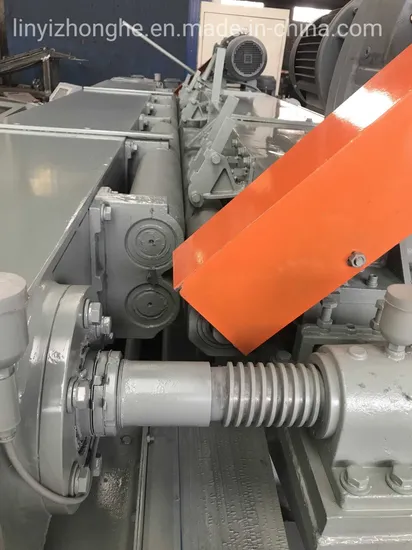

| Model NO. | WXQ-2700L-550S |

| Type | Hot Press Machine |

| Automatic | Semi-Automatic |

| Certification | CE, ISO |

| Color | Customize |

| Peeling Thickness | 1.5 mm - 3.6 mm |

| Peeling Speed | 0-90 Meters Per Minute |

| Total Motor Power | 45 Kw |

| Electricity Standard | 380V, 50 Hz , 3 Phases |

| Transport Package | Plastic Film / Plywood |

| Specification | 5000*2500*1450 mm |

| Trademark | ZHONGHE |

| Origin | Linyi City, China |

| HS Code | 8465960000 |

| Production Capacity | 1 Sets / Month |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

High Speed Knife Sharpener Grinding Machine From Linyi Manufacturer and Supplier Excellence

Price: $6900.00 per piece

Heavy-Duty Hydraulic Lift Table for Industrial Use Bulk Manufacturing Processing

Price: $800.00 per piece

Spindle Plywood Veneer Peeling Machine China Made Contract-Based Manufacturing

Price: $13500.00 per piece