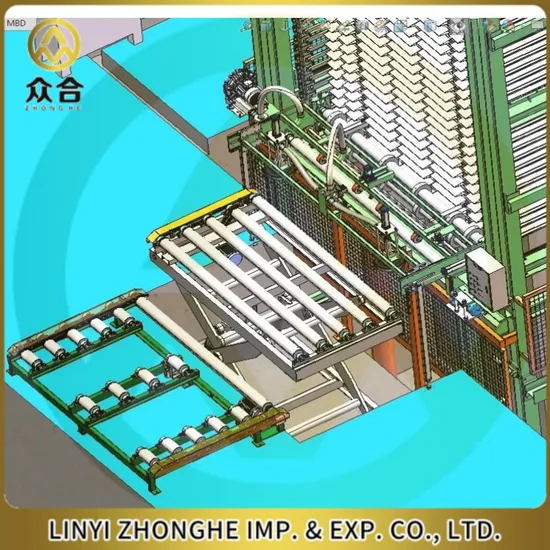

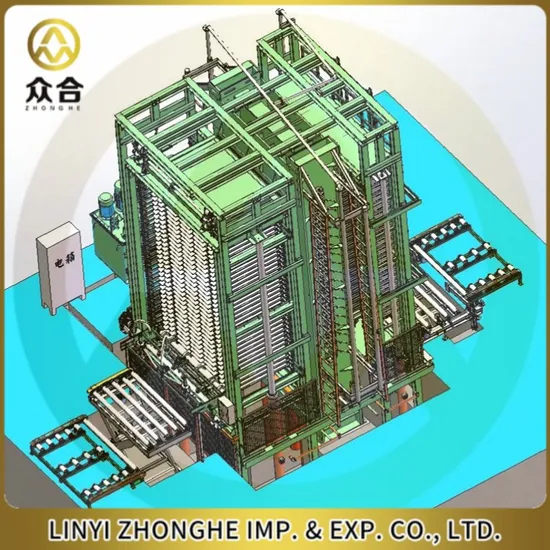

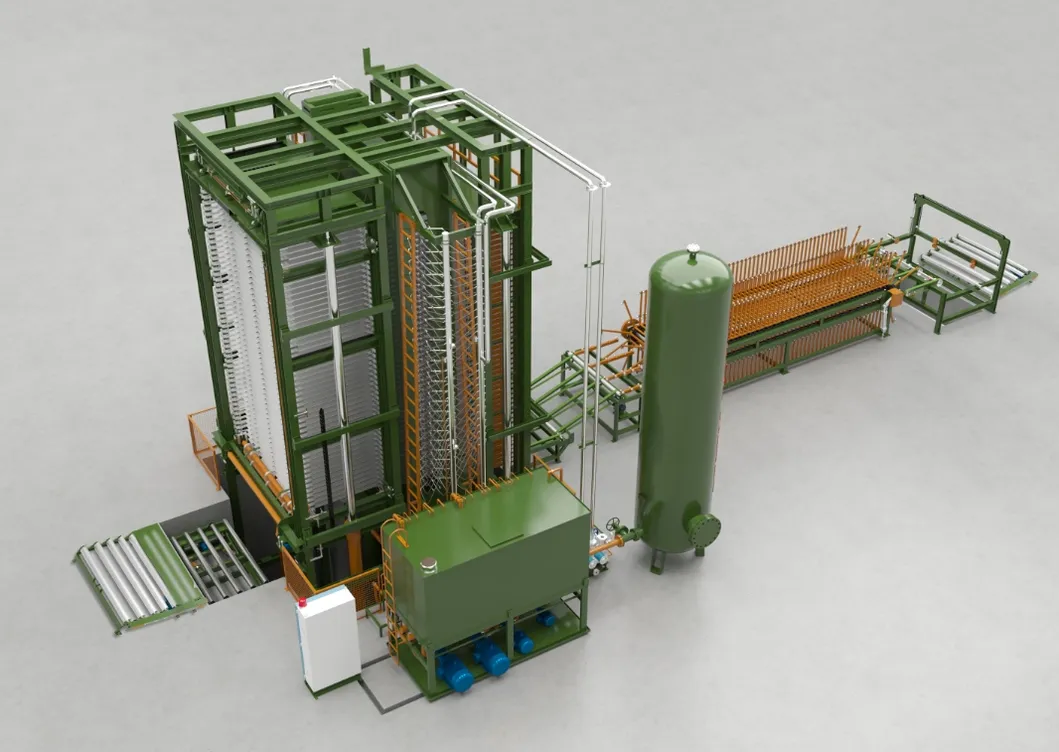

Selling New Products Full-Automatic Plywood Production Line Advanced Chinese Plywood Making Machine with Loader and Unloader Affordable Factory Pricing Partners

Category

Machinery

Sub-Category

Woodworking Machinery

Completed orders

0

Price

$140000.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

| Type | Hot Press Machine |

| Automatic | Automatic |

| Certification | CE, ISO |

| Color | Customize |

| Function | Put Pressure on The Plywood |

| Low Pressure Pump Motor Power | 22 Kw, 2 Pieces |

| Total Motor Power | 64.7 Kw |

| Place of Origin | Shandong, China |

| Condition | New |

| Usage | Plywood Production |

| Key Selling Points | Easy to Operate and Durable |

| Transport Package | Plastic Film / Plywood |

| Specification | 4220*2020*11300 mm |

| Trademark | ZHONGHE |

| Origin | Linyi City, China |

| HS Code | 847930000 |

| Production Capacity | 3 Sets / Month |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Hot Press Machine Woodworking Pressing Machines Door Pressing Natural Veneer Wholesale Trade Supplier

Price: $12500.00 per piece

Simple Maintenance Wood Log Bark Peeling Machine Custom Factory Production

Price: $8500.00 per piece

Advanced PVC Door Manufacturing Hot Press Machine Factory to Consumer Hub

Price: $20500.00 per piece

Accurate Double Dimension Trimming Saw Private Label Manufacturing

Price: $13000.00 per piece