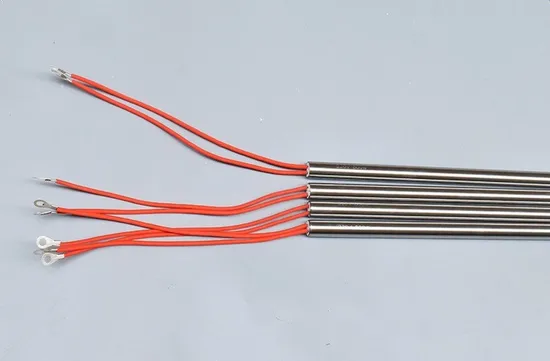

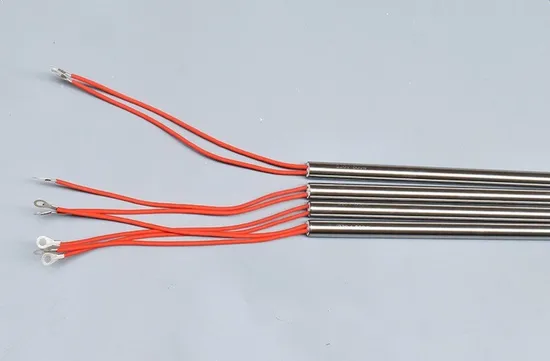

Tubular Heating Element Cartridge Heater for Plastic Package Sealing Industrial Heater

| Material | Stainless Steel |

| Form | Heating Wire |

| Shape | Tubular |

| Model No. | CO2 |

| Tube Diameter | 6mm-30mm |

| Max Temperature | 870c(1600f) |

| Application | Gas, Oil, Water, Plastic |

| After-Sales Service Provided | Overseas Third-Party Support Available |

| Power | 50W-10kw |

| Resistance Heating Wire | Nicr 80/20 Wire |

| Insulation Resistance (Cold) | ≥ 500 MΩ |

| Length Tolerance | ±1 mm |

| Resistance Tolerance | +10%, -5% |

| Dia Tolerance | +0.05mm -0.1mm (+.002" -.004") |

| Voltage | 12-380V |

| Style | Cartridge |

| Transport Package | Paper Box |

| Specification | can be customized |

| Trademark | Cheri |

| Origin | China |

| HS Code | 8516800000 |

| Production Capacity | 10000000/Year |

Product Description: Tubular Heating Element Cartridge Heater for Plastic Package Sealing – Cheri Heater Technology Co., Ltd.

Elevate your industrial packaging process with the Tubular Heating Element Cartridge Heater from Cheri Heater Technology Co., Ltd. Designed specifically for plastic package sealing, this state-of-the-art heating solution is engineered to meet the rigorous demands of industrial applications while ensuring efficiency and reliability. Our cartridge heater is the perfect choice for manufacturers looking to enhance their sealing processes with precision-engineered thermal solutions.

Key Features:

-

High-Quality Construction:

Each tubular heating element is constructed from premium materials that guarantee durability and performance. The stainless-steel sheath ensures corrosion resistance, extending the life of the heater even in demanding environments.-

High Efficiency:

With advanced heating technology, our cartridge heater provides rapid heat-up times and even temperature distribution. This efficiency not only speeds up your production process but also helps to minimize energy consumption, leading to cost savings.-

Versatile Design:

Our cartridge heater is available in various diameters and lengths to fit seamlessly into your existing machinery. Whether you’re working with different types of plastic films or packaging materials, this tubular heating element can be customized to meet your specifications.-

Temperature Control:

Designed to operate at high temperatures, our heater can reach up to 400°C (752°F) with precise temperature control. This capability ensures that your plastic sealing is always optimal, preventing missealing and enhancing product integrity.-

Easy Installation:

The lightweight and compact design of our cartridge heater makes installation a breeze. It is compatible with various industrial sealing machines and can be easily integrated into both existing and new systems.-

Enhanced Safety Features:

Our tubular heating element is designed with safety in mind. Built-in overheat protection ensures that the heater operates within safe temperature limits, reducing the risk of accidents and material degradation.Applications:

The Tubular Heating Element Cartridge Heater is ideal for a wide range of applications in the packaging industry, including but not limited to:

-

Plastic Packaging Sealing:

Perfect for sealing plastic films and containers, ensuring airtight seals that preserve product freshness.-

Food and Beverage Industries:

Essential for packaging products that require stringent hygiene standards while maintaining excellent sealing quality.-

Pharmaceutical Packaging:

Guarantees reliable sealing for pharmaceutical products, adhering to industry regulations and safety standards.-

General Manufacturing:

Suitable for diverse manufacturing processes that involve the sealing of plastic components.Technical Specifications:

-

Material:

Stainless Steel -Max Operating Temperature:

400°C (752°F) -Power Range:

Customizable to meet specific heating requirements. -Watt Density:

Designed for optimal heat transfer to ensure consistent performance.-

Custom Lengths and Diameters Available:

Tailored to fit a variety of machinery and applications.Why Choose Cheri Heater Technology Co., Ltd.?

At Cheri Heater Technology Co., Ltd., we are committed to providing industry-leading thermal solutions that enhance operational efficiency and product quality. Our team of experienced engineers and technicians work diligently to develop innovative heating technologies that cater to the specific needs of our clients. With a strong focus on customer satisfaction, we pride ourselves on our timely delivery, competitive pricing, and exceptional after-sales support.

Customer Support and Warranty:

Our dedication to quality doesn’t stop at the product. Cheri Heater Technology Co., Ltd. offers comprehensive customer support, including installation guidance and troubleshooting advice. We stand behind our products with a robust warranty, ensuring that you receive the peace of mind you deserve when investing in our heating solutions.

Contact Us:

Ready to revolutionize your plastic sealing processes? Contact Cheri Heater Technology Co., Ltd. today to learn more about our Tubular Heating Element Cartridge Heater and how it can benefit your production line. Our team is here to assist you in selecting the right heating solution tailored to your specific application needs.

Optimize Your Production with Cheri Heater Technology Co., Ltd.

Transform your packaging operations with the Tubular Heating Element Cartridge Heater designed for optimal performance and reliability. When you choose Cheri Heater Technology Co., Ltd., you're not just purchasing a product; you’re investing in advanced heating technology that will enhance your production efficiency while maintaining the quality of your packaged goods.

Explore our extensive range of high-performance heating elements and let us help you achieve your production goals today!