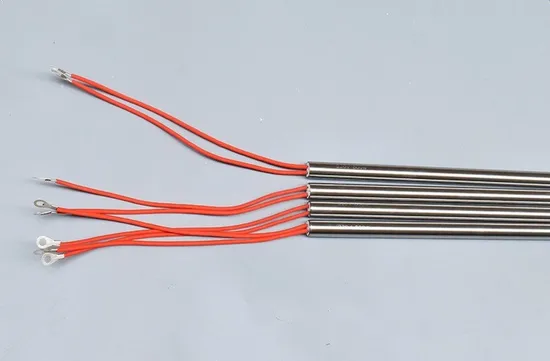

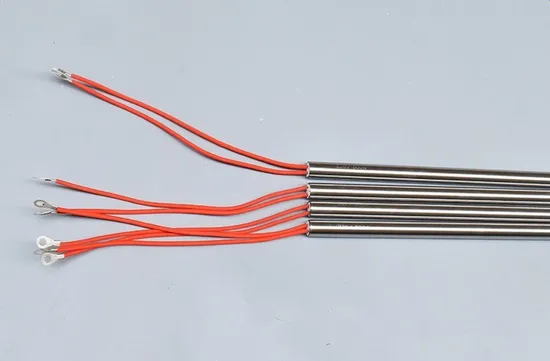

Mold Machine Tubular/ Electric Heating Element Cartridge Heater /Customized

| Material | Stainless Steel |

| Form | Heating Wire |

| Shape | Tubular |

| Model No. | CO2 |

| Tube Diameter | 6mm-30mm |

| Max Temperature | 870c(1600f) |

| Application | Gas, Oil, Water, Plastic |

| After-Sales Service Provided | Overseas Third-Party Support Available |

| Power | 50W-10kw |

| Resistance Heating Wire | Nicr 80/20 Wire |

| Insulation Resistance (Cold) | ≥ 500 MΩ |

| Length Tolerance | ±1 mm |

| Resistance Tolerance | +10%, -5% |

| Dia Tolerance | +0.05mm -0.1mm (+.002" -.004") |

| Voltage | 12-380V |

| Style | Cartridge |

| Transport Package | Paper Box |

| Specification | can be customized |

| Trademark | Cheri |

| Origin | China |

| HS Code | 8516800000 |

| Production Capacity | 10000000/Year |

Product Description: Customized Tubular Electric Heating Element Cartridge Heater by Cheri Heater Technology Co., Ltd.

---

Product Overview:

Introducing the exceptional

Mold Machine Tubular Electric Heating Element Cartridge Heater

from Cheri Heater Technology Co., Ltd. Designed for precision heating applications, our custom-made cartridge heaters are engineered to maximize efficiency and performance in various industrial settings. Whether you’re in the mold making, plastic processing, or any other heating-demanding field, our cartridge heaters deliver reliable heat distribution and quick response times, ensuring optimal production outcomes.Key Features:

-

Customizable Designs

: At Cheri Heater Technology Co., Ltd., we understand that every application is unique. That’s why we offer customizable options for our tubular electric heating element cartridge heaters. Tailor dimensions, wattage, and voltage specifications to meet your specific operational needs, ensuring compatibility and reliability in any setup.-

High-Efficiency Heating

: Our cartridge heaters are meticulously designed for high-efficiency heating. Utilizing advanced manufacturing techniques, they provide uniform heat distribution, lowering energy consumption and enhancing performance in your mold machines or other applications.-

Durability and Longevity

: Constructed from high-quality materials, our tubular electric heating elements are built to last. With excellent resistance to oxidation and corrosion, these heaters can withstand harsh environments and heavy usage, reducing downtime and maintenance costs.-

Rapid Heat-Up Time

: The Mold Machine Tubular Electric Heating Element is engineered for rapid heat-up times, allowing for quick cycles in your manufacturing process. Experience shorter waiting times and increased productivity with our efficient heating solutions.-

Versatile Applications

: Our cartridge heaters are suitable for a wide range of applications including but not limited to: - Injection molding machines - Extruders - Dies and heating molds - Packaging machinery - Food processing equipment - Medical devices-

Safety First

: Safety is paramount in any industrial environment. Our heating elements meet stringent safety standards, which helps minimize risks associated with overheating and electrical failures. The design ensures that it operates safely under a wide range of conditions.-

Easy Installation

: The cartridge heater's user-friendly design allows for easy installation and replacement. This feature simplifies the heating element setup or upgrade processes, minimizing disruption to your workflow.Specifications:

-

Material

: High-grade stainless steel, high-temperature insulators -Diameter Range

: Customizable from 6mm to 25mm -Length

: Tailored options from 50mm to 600mm -Wattage

: Ranges from 25W to 1200W based on requirements -Voltage

: Custom options available (110V, 220V, 380V) -Thermal Conductivity

: Optimized for rapid heat transmission -Insulation

: Class 1 and Class 2 insulation options availableWhy Choose Cheri Heater Technology Co., Ltd.?

With years of experience in the heating solutions industry, Cheri Heater Technology Co., Ltd. has established itself as a leading manufacturer. Our commitment to quality, innovation, and customer satisfaction drives us to create heating products that not only meet but exceed your expectations. When you choose our Mold Machine Tubular Electric Heating Element Cartridge Heater, you are choosing reliability, efficiency, and customized solutions tailored to your specific application needs.

Customer-Focused Solutions:

At Cheri Heater Technology Co., Ltd., we prioritize our customers’ needs. Our technical team works closely with you from the initial design phase to the final product delivery, ensuring that every heater we manufacture is precisely tailored to your requirements. We also provide excellent after-sales support, helping you troubleshoot any issues and ensuring your heating systems remain operational and efficient.

Industry Applications:

-

Plastic Manufacturing

: Ensure smooth melt flow and consistent product quality with our precision heating elements designed for molding and extrusion processes. -Automotive Industry

: Utilize our cartridge heaters for a variety of applications, including composite curing and dashboard heating, contributing to better quality control. -Medical Equipment

: Depend on our reliability for the manufacture of medical devices where precise temperatures and safety are critical.-

Food Processing

: Maintain the ideal temperature for food processing and cooking equipment, preventing product spoilage and maintaining quality.Customization Process:

Our straightforward customization process allows you to specify your requirements with ease. Provide us with the necessary specifications such as dimensions, wattage, voltage, and any special features you need, and our engineers will develop a direct solution tailored for you.

Quality Assurance:

Every Mold Machine Tubular Electric Heating Element cartridge heater undergoes rigorous testing to ensure it meets Cheri Heater Technology's high standards of quality and efficiency. From raw materials to the final product, we maintain strict quality control protocols to guarantee that each unit delivered to our customers is of the utmost quality.

Conclusion:

Enhance your manufacturing efficiency and reliability with the Mold Machine Tubular Electric Heating Element Cartridge Heater by Cheri Heater Technology Co., Ltd. The superior performance, durability, and customizable options ensure you receive the best heating solution tailored to your specific requirements. Trust Cheri Heater Technology to deliver heating solutions that power your success.

For inquiries and to discuss your project needs, contact our sales team today, and let us help you find the perfect heating solution tailored to your operational demands.