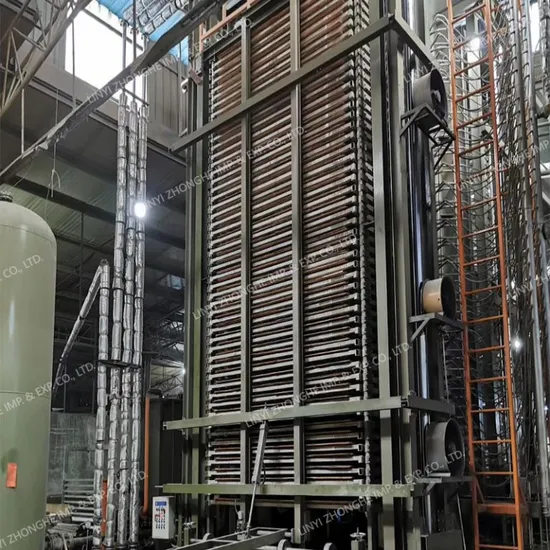

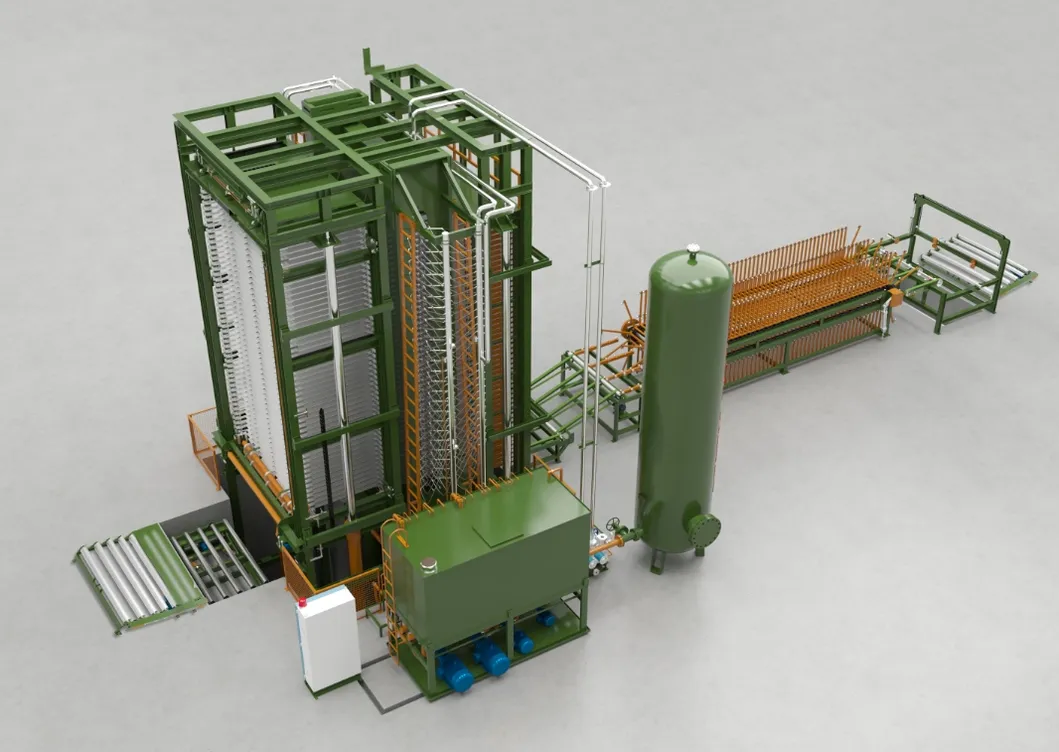

Assembled Multi Layers 500t/600t/800t Hot Press for Plywood Making Machine

| Type | Hot Press Machine |

| Automatic | Automatic |

| Certification | CE, ISO |

| Color | Customize |

| Function | Put Pressure on The Plywood |

| Low Pressure Pump Motor Power | 22 Kw, 2 Pieces |

| Total Motor Power | 64.7 Kw |

| Place of Origin | Shandong, China |

| Condition | New |

| Usage | Plywood Production |

| Key Selling Points | Easy to Operate and Durable |

| Transport Package | Plastic Film / Plywood |

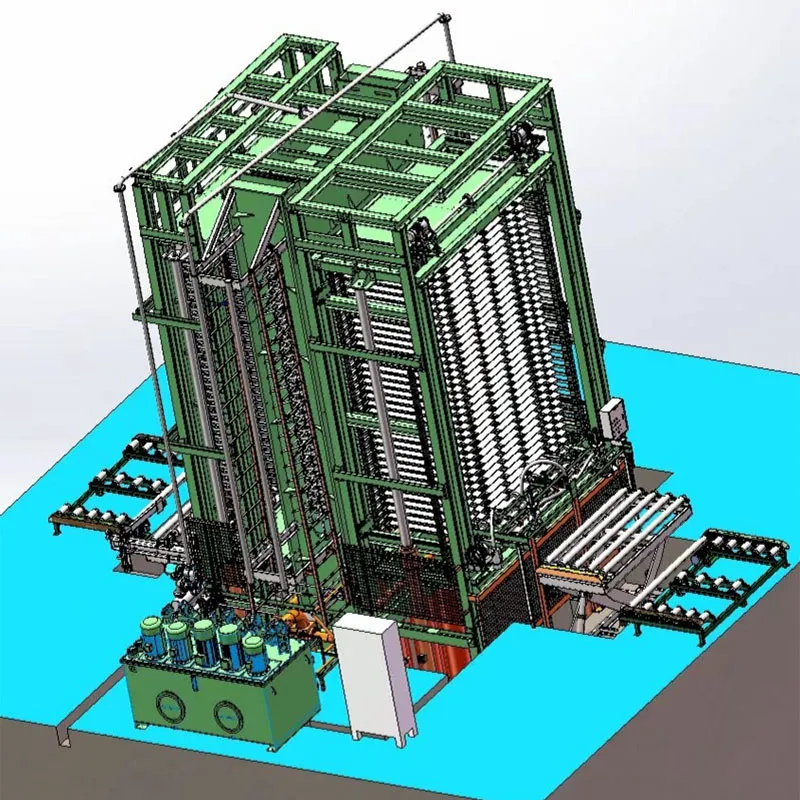

| Specification | 4220*2020*11300 mm |

| Trademark | ZHONGHE |

| Origin | Linyi City, China |

| HS Code | 847930000 |

| Production Capacity | 3 Sets / Month |

Product Description: Assembled Multi Layers 500t/600t/800t Hot Press for Plywood Making Machine

Introducing the Assembled Multi Layers Hot Press: The Pinnacle of Plywood Manufacturing Technology

Transform your plywood production with the state-of-the-art Assembled Multi Layers 500t/600t/800t Hot Press, exclusively from Linyi Zhonghe Import & Export Co., Ltd. This advanced hot press machine is engineered to optimize your manufacturing process, ensuring consistent quality, enhanced efficiency, and exceptional durability in every batch of plywood.

Key Features:

1.

Versatile Capacity Options:

Our hot press machine is available in three robust configurations—500 tons, 600 tons, and 800 tons—allowing you to choose the perfect size according to your operational requirements. Whether you are a small workshop or a large-scale production facility, the Assembled Multi Layers Hot Press adapts seamlessly to your needs.2.

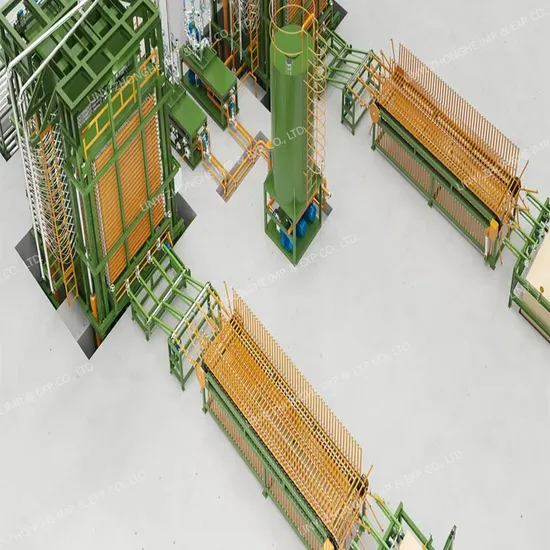

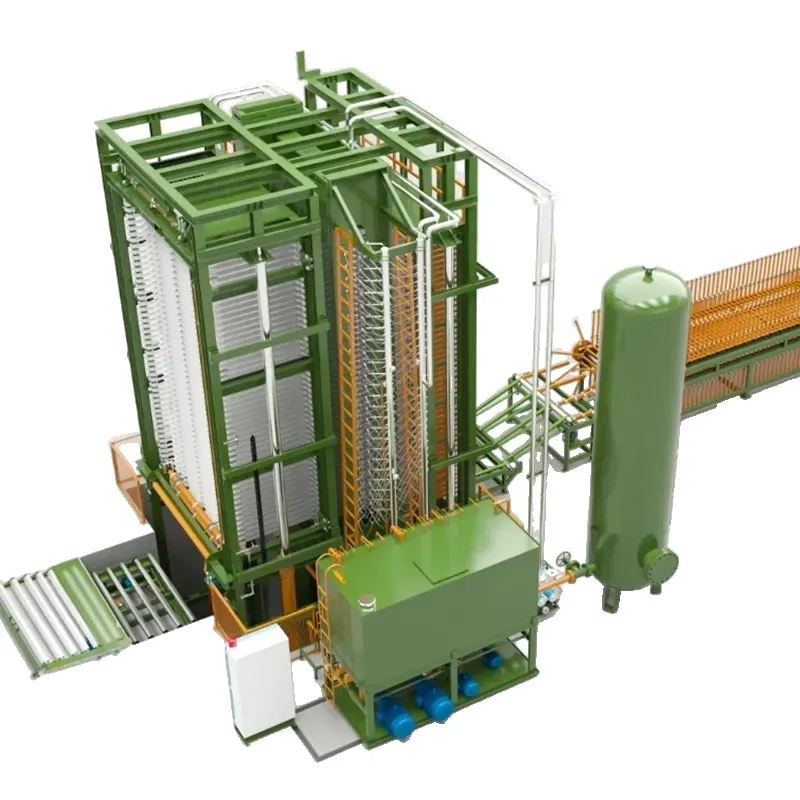

Multi-Layer Design:

The innovative multi-layer design of our hot press enhances productivity while reducing cycle times. The ability to process multiple layers at once not only speeds up your production but also ensures uniform heating and pressing, resulting in superior quality plywood sheets.3.

Advanced Heating Technology:

Equipped with cutting-edge heating elements, our hot press delivers rapid and even heat distribution across the surface. This ensures that adhesives cure thoroughly, resulting in optimal bonding strength and minimizing defects in the plywood. The system is designed to maintain precise temperature control, tailored specifically for different wood types and adhesives.4.

Durable Build Quality:

Built from high-quality materials, the Assembled Multi Layers Hot Press guarantees longevity and reliability. The robust frame and specially treated components provide resistance to wear and tear, ensuring that your investment serves your production needs for years to come.5.

User-Friendly Controls:

The intuitive control panel simplifies operation, making it easy for your workforce to manage production parameters. Features include digital displays for temperature and pressure, customizable settings for different wood species and adhesives, and automatic timers to streamline your workflow.6.

Energy Efficiency:

Our hot press is designed with energy conservation in mind. The efficient heating system and insulation minimize energy consumption, reducing operational costs without compromising output or quality. Make the shift towards sustainable manufacturing with our energy-efficient solution.7.

High Safety Standards:

Safety is paramount in any manufacturing environment. The Assembled Multi Layers Hot Press is designed with multiple safety features, including automatic shut-off mechanisms, pressure release valves, and emergency stops, ensuring a secure operational environment for your staff.8.

Flexible Application:

Whether you’re producing furniture, flooring, or decorative panels, this hot press is versatile enough to accommodate a wide range of plywood thicknesses and dimensions. Perfect for crafting high-quality birch, poplar, and hardwood plywood, the machine elevates your product offerings significantly.9.

Ease of Maintenance:

Designed for easy upkeep, the hot press incorporates features that facilitate routine maintenance. Simple access points allow for quick inspection and cleaning, ensuring your machine operates smoothly without extended downtime.10.

Expertise from Industry Leaders:

With years of experience in the machinery manufacturing sector, Linyi Zhonghe Import & Export Co., Ltd. is committed to delivering high-quality products backed by exceptional customer service. Our team of experts is always available to provide guidance on best practices and maintenance, ensuring you get the most out of your machinery.Applications:

This Assembled Multi Layers Hot Press is suitable for various applications within the plywood industry, including:

-

Furniture Manufacturing:

Ideal for creating durable and aesthetically appealing wooden furniture pieces, allowing for high production rates without compromising quality.-

Flooring Production:

Perfect for manufacturing plywood used in floor panels, combining strength with an attractive finish.-

Construction and Building Materials:

Create high-quality structural plywood that can withstand the rigors of construction while still maintaining usability and appearance.-

Custom Applications:

The versatility of our hot press allows for specialized applications, making it a valuable asset in any innovative wood processing operation.Why Choose Linyi Zhonghe Import & Export Co., Ltd.?

-

Unmatched Quality Assurance:

We adhere to rigorous quality control processes throughout our manufacturing operations, ensuring that every hot press that leaves our facility meets the highest standards.-

Tailored Solutions:

We understand that each customer has unique needs. Our team works closely with you to provide tailored solutions that fit your specific operational demands.-

Global Reach:

With a robust distribution network, our products are available globally. Trust in a company that prides itself not just on quality machines but also on impeccable service.-

Affordable Pricing:

Our competitive pricing strategy ensures that you receive excellent value for your investment. High quality doesn’t have to come at a steep price—experience the best without breaking the bank.

Unlock the potential of your plywood production with the Assembled Multi Layers 500t/600t/800t Hot Press from Linyi Zhonghe Import & Export Co., Ltd. Elevate your manufacturing capabilities, enhance product quality, and increase profitability. Get ready to redefine your plywood making process with this ultimate investment in manufacturing excellence!