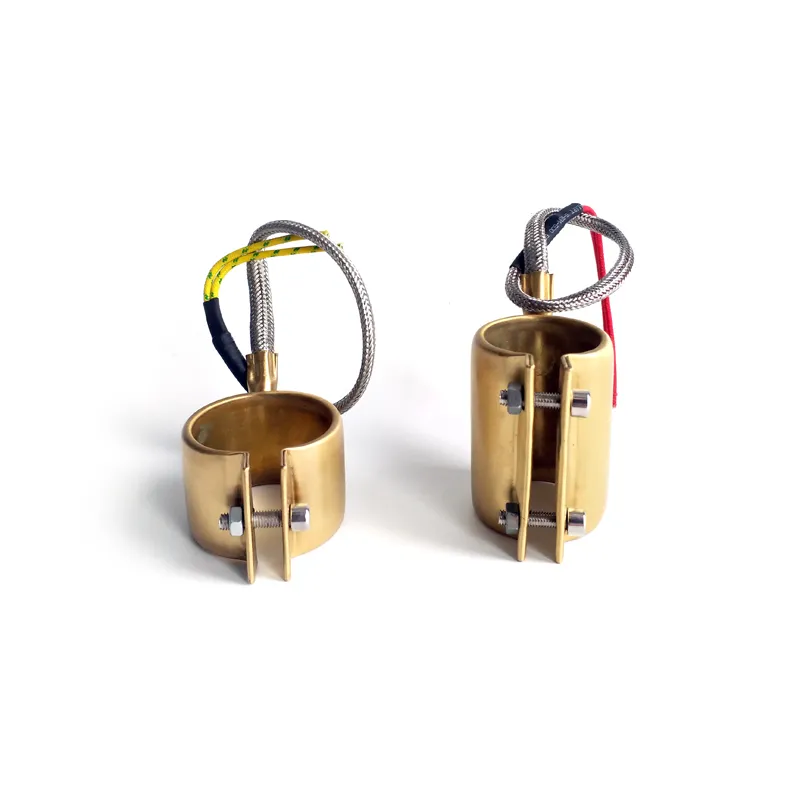

Meltblown Equipment Machinery Heating Barrel Heater High-Volume Manufacturing

Category

Electrical Equipment & Supplies

Sub-Category

Refrigeration & Heat Exchange Accessories

Completed orders

0

Price

$4.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Tongji Road, Gehuang Industrial Concentration Zone, Zhangguo Community, Dainan Town, Xinghua City, TaiZhou, Jiangsu, China

| Material | Brass |

| Form | Band Heater |

| Shape | Round |

| Application | Plastic |

| After-Sales Service Provided | Overseas Third-Party Support Available |

| Power | 50W-10kw |

| Resistance Heating Wire | Nicr 80/20 Wire |

| Insulation Resistance (Cold) | ≥ 500 MΩ |

| Length Tolerance | ±1 mm |

| Resistance Tolerance | +10%, -5% |

| Dia Tolerance | +0.05mm -0.1mm (+.002" -.004") |

| Voltage | 12-380V |

| Transport Package | Paper Box |

| Specification | can be customized |

| Trademark | Cheri |

| Origin | China |

| HS Code | 8516800000 |

| Production Capacity | 100000/Year |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Factory Silicone Rubber Flexible Heater Heating Pad Barrel Drum Heater Export Factory

Price: $1.00 per piece