Laminated Melamine Paper Plywood Hot Press Production Line Machines China Exporter B2B

Category

Machinery

Sub-Category

Woodworking Machinery

Completed orders

0

Price

$140000.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

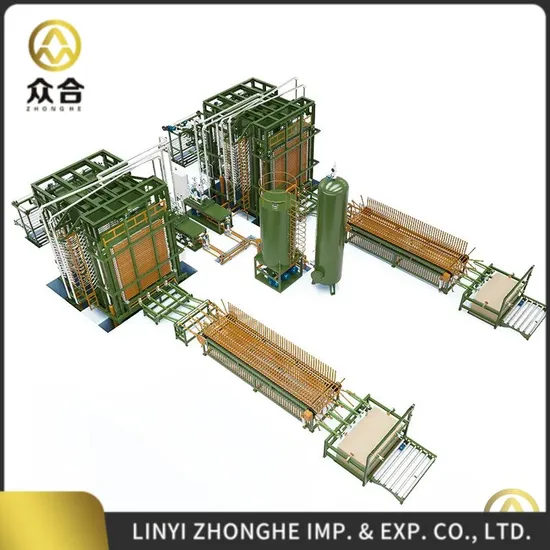

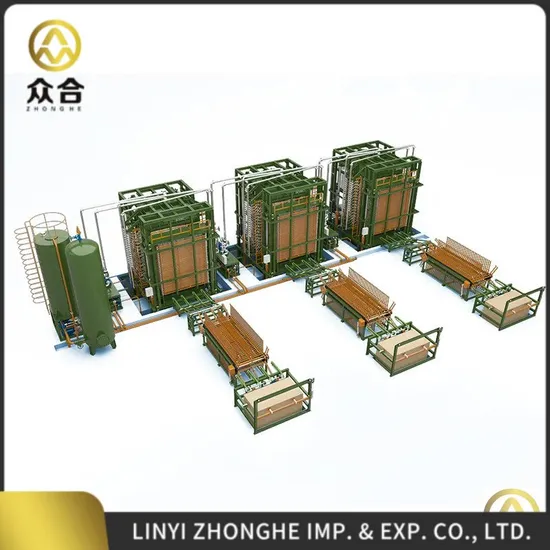

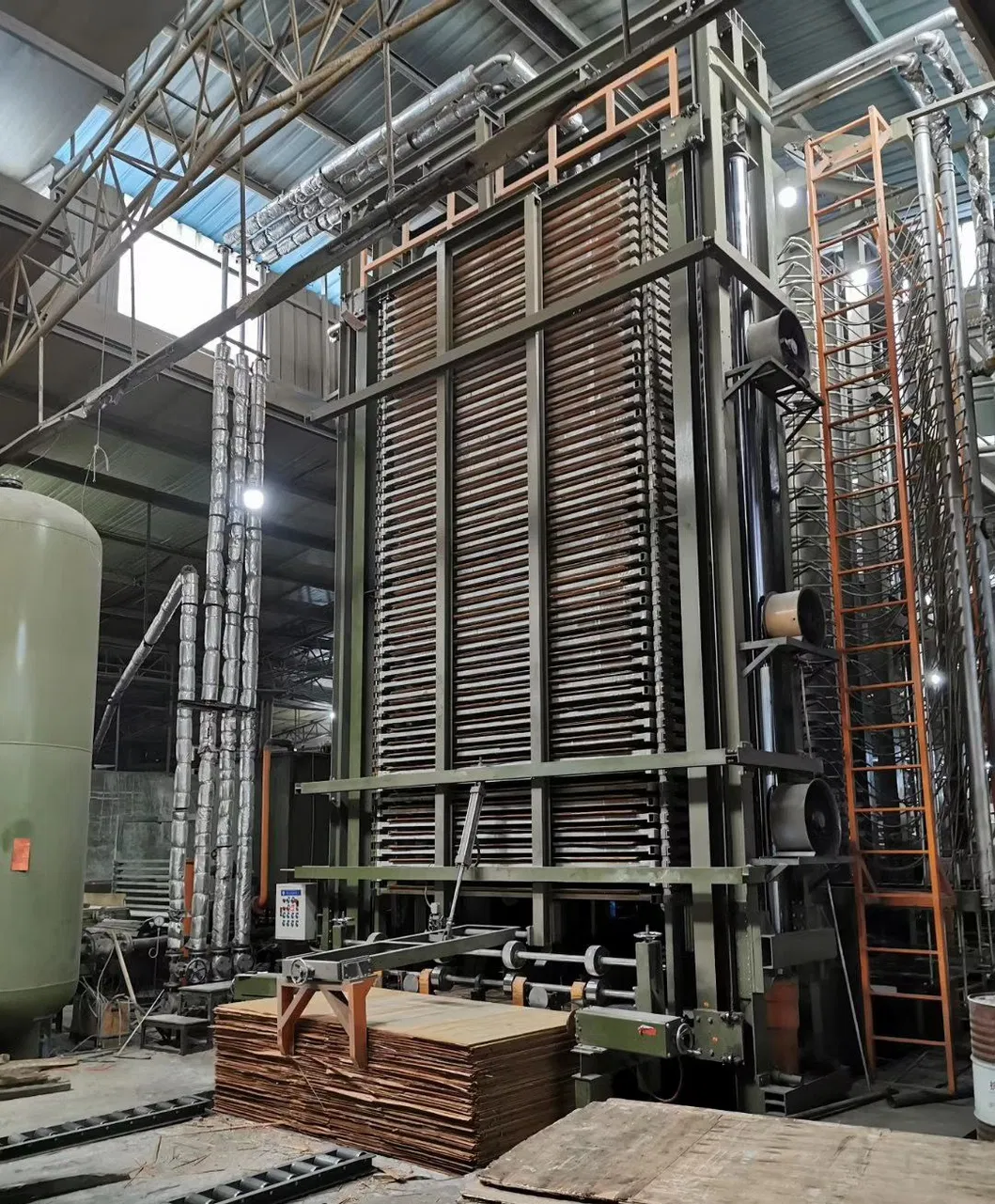

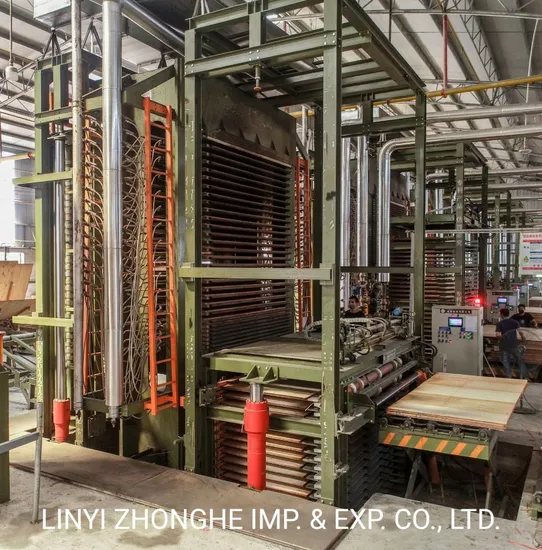

| Model NO. | BRY-4*8-600T-25L |

| Type | Hot Press Machine |

| Automatic | Automatic |

| Certification | CE, ISO |

| Color | Customize |

| Function | Put Pressure on The Plywood |

| Low Pressure Pump Motor Power | 22 Kw, 2 Pieces |

| Total Motor Power | 64.7 Kw |

| Transport Package | Plastic Film / Plywood |

| Specification | 4220*2020*11300 mm |

| Trademark | ZHONGHE |

| Origin | Linyi City, China |

| HS Code | 847930000 |

| Production Capacity | 3 Sets / Month |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Plywood Wood Panel 4 Four Side Edge Trimming Cutting Machine Industrial Exporter

Price: $13000.00 per piece

Hot Selling 50 Layers Full Automatic Plywood Hot Press From China Wholesale Factory

Price: $230000.00 per piece

Wood Peeling Log Debark Machine Made in China Global Wholesale Market Operations

Price: $10000.00 per piece

China Efficient Wood Debarker Use for Plywood Making China Manufacturing

Price: $10000.00 per piece