Ideal for Use in The Plastic Process Industry or in Applications Where It′ S Needed Flexible Thermocouple Product Sourcing

Category

Electrical Equipment & Supplies

Sub-Category

Refrigeration & Heat Exchange Accessories

Completed orders

0

Price

$1.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Tongji Road, Gehuang Industrial Concentration Zone, Zhangguo Community, Dainan Town, Xinghua City, TaiZhou, Jiangsu, China

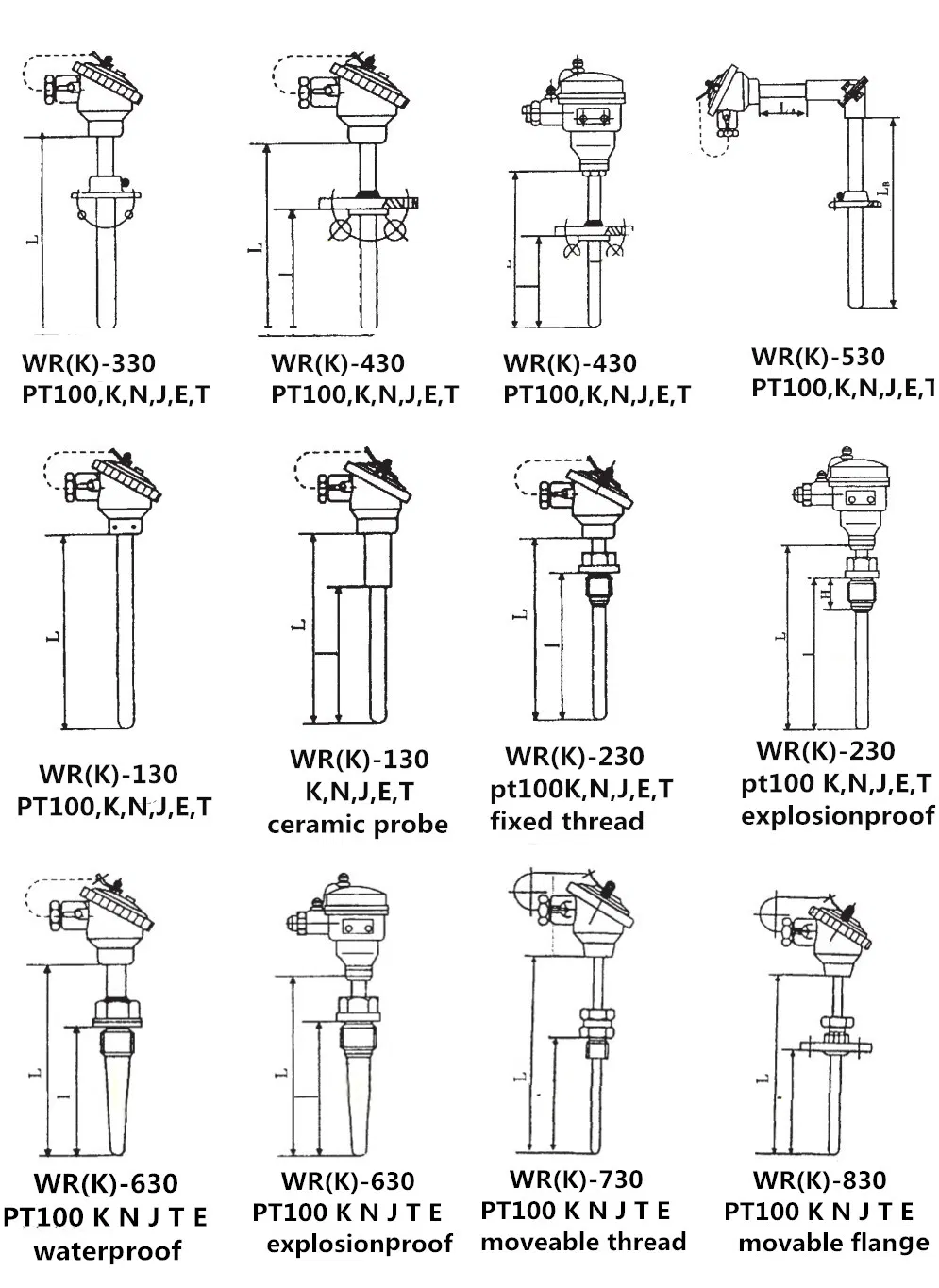

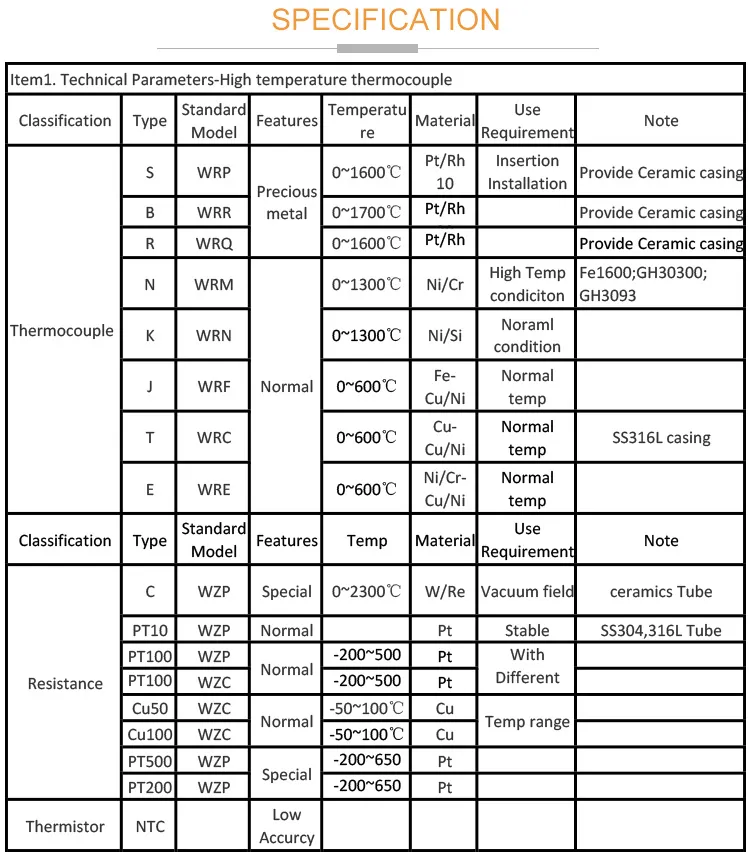

| Type | K J T E N S B R PT100 Cu50 Ntc |

| Measuring Medium | Gas,Liquid,Solid |

| Measuring Range | -100-1600°c |

| Transport Package | Paper Box |

| Specification | can be customized |

| Trademark | Cheri |

| Origin | China |

| HS Code | 9025199090 |

| Production Capacity | 100000/Year |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Heating Electric Pipe Freeze Protection Heat Cable Customized Manufacturing Solutions

Price: $15.00 per piece

Self Regulating Antifreeze Heat Trace Cable with Tinned Copper Factory-Owned Wholesale

Price: $15.00 per piece