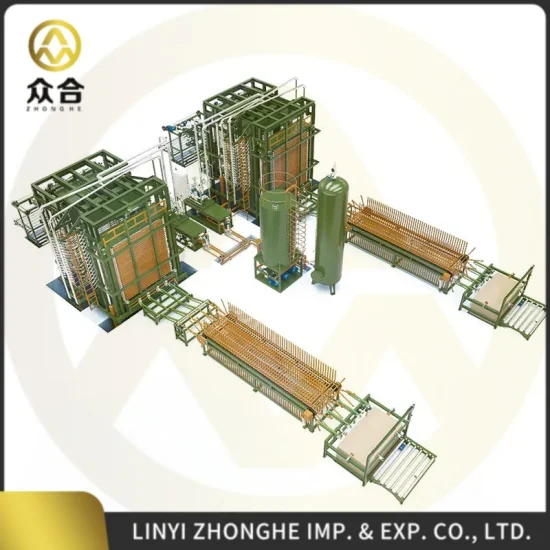

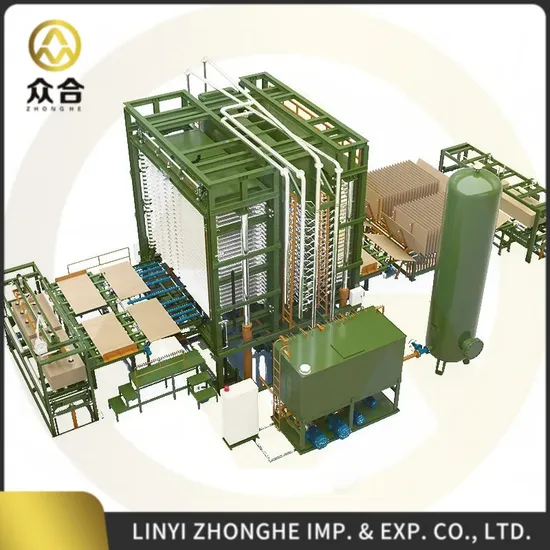

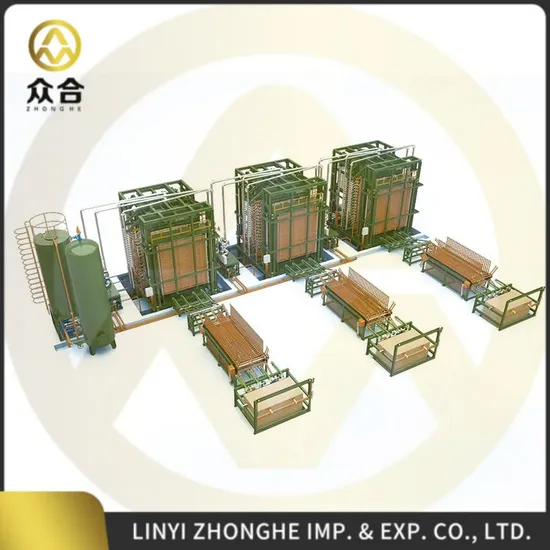

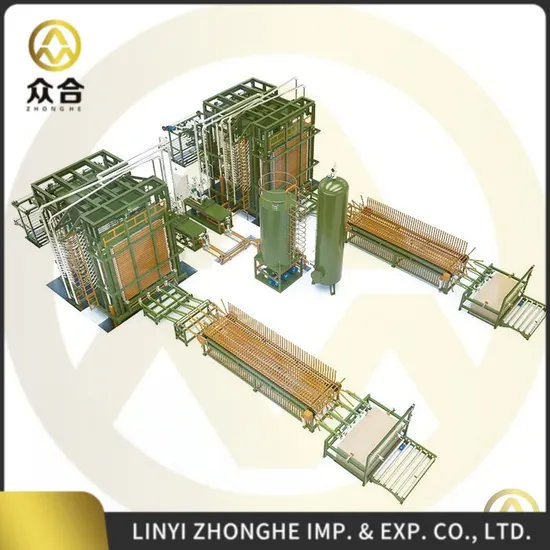

Full Set Wood Veneer Plywood Hot Press Making Machine Quality Manufacturing

Category

Machinery

Sub-Category

Woodworking Machinery

Completed orders

0

Price

$140000.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

| Type | Hot Press Machine |

| Automatic | Automatic |

| Certification | CE, ISO |

| Color | Customize |

| Function | Put Pressure on The Plywood |

| Low Pressure Pump Motor Power | 22 Kw, 2 Pieces |

| Total Motor Power | 64.7 Kw |

| Transport Package | Plastic Film / Plywood |

| Specification | 4220*2020*11300 mm |

| Trademark | ZHONGHE |

| Origin | Linyi City, China |

| HS Code | 847930000 |

| Production Capacity | 3 Sets / Month |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Hot Press Machine for Film Faced Plywood Production Factory Direct Sales

Price: $140000.00 per piece

Automatic Wood Hydraulic Hot Press Machine for Plywood Doors Custom Factory Production Trade

Price: $12500.00 per piece

Door Panel Hot Press Made in China Mass Market Wholesale Customization

Price: $20500.00 per piece

Steady 10 Feet Wood Debarker for Plywood Making Manufacturing & Supply Trade

Price: $8500.00 per piece