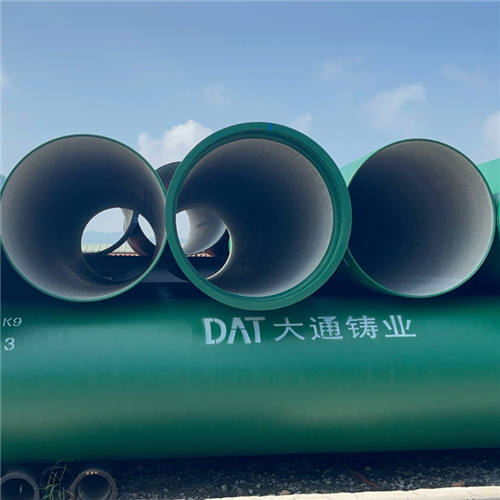

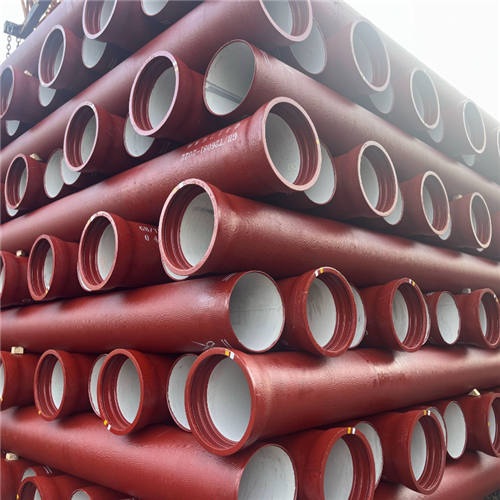

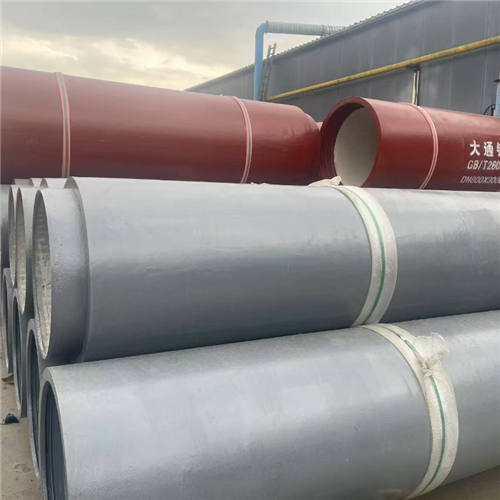

Ductile Iron Pipe for Fire Fighting System

Category

Sub-Category

Completed orders

Price

Delivery Cost

Minimum Order

Location

A fire fighting system must ensure continuous water supply, stable water pressure, and immediate response capability. Any leakage, pipe failure, or pressure drop may cause significant safety risks. Ductile iron pipe provides the reliability and strength required to support these mission-critical conditions.

Key Advantages of Ductile Iron Pipe for Fire Fighting Systems

High Pressure Resistance

Fire fighting networks often operate under high water pressure, particularly in high-rise buildings, municipal fire mains, and industrial fire protection loops. Ductile iron pipe demonstrates stable performance under both normal and surge pressure, ensuring consistent flow delivery during fire emergencies.

Excellent Mechanical Strength

In underground installations and above-ground exposed systems, ductile iron pipe withstands traffic loads, soil displacement, external impact, and vibration. This makes it suitable for both municipal fire water pipelines and industrial fire protection systems that require long-term durability.

Reliable Joint Sealing

Fire protection systems demand zero leakage and immediate pressurization. Rubber sealing rings produced according to ISO 4633 and EN 681-1 ensure tight and flexible joints, maintaining stability even during pressure fluctuations or thermal expansion.

Superior Corrosion Resistance

Fire fighting pipelines may be exposed to humidity, saline soil environments, outdoor weathering, or industrial contaminants. The combination of zinc spraying and protective coatings provides long-term corrosion resistance, reducing maintenance costs and extending service life.

Long-Term Safety Performance

The stability of ductile iron pipe over decades makes it particularly suitable for critical fire water supply systems. Its predictable performance and low maintenance needs minimize operational risk for buildings, factories, and municipal infrastructure.

For more information please visit www.datpipes.com

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Ductile Iron Pipe Erternal Paint with Epoxy

DI jacking pipe