China Manufacturer Two Roller Wood Debarker and Log Wood Debarking Machine ODM Manufacturing Direct

Category

Machinery

Sub-Category

Other Machinery & Industry Equipment

Completed orders

0

Price

$18000.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

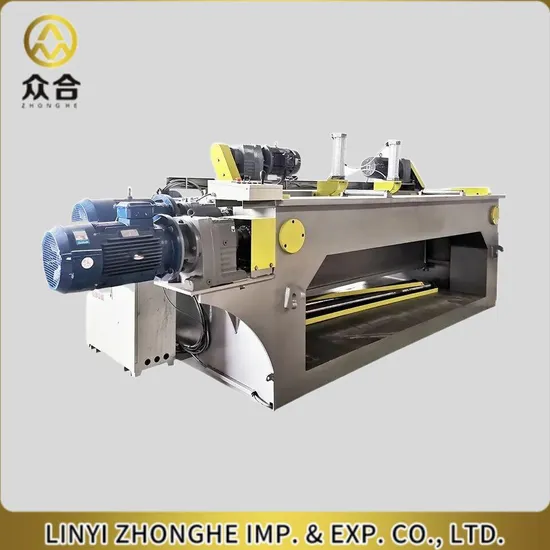

| Model NO. | WXQ2700-450 |

| Type | Veneer Peeling Machine |

| Automatic | Semi-Automatic |

| Certification | CE |

| Machine Usage | Peel Wood Log Into Veneer |

| Veneer Thickness | 0.5 mm to 3.6 mm |

| Peeling Speed | 0-110 Meters/Min |

| Machine Colour | Customize |

| Key Selling Points | High-Accuracy |

| Machinery Test Report | Provided |

| Transport Package | Plastic Film |

| Specification | 4900*2500*1450mm |

| Trademark | Zhonghe |

| Origin | Linyi City, Shandong Province, China |

| HS Code | 846596000 |

| Production Capacity | 10 Sets Per Month |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

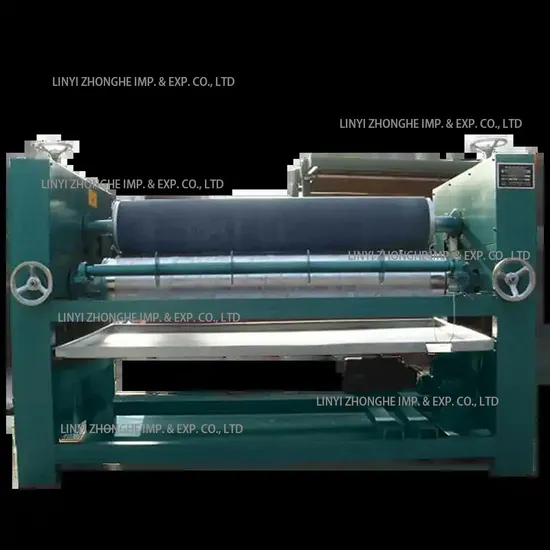

MDF Gluing Machine Gumming Machine for MDF Board Mass Wholesale

Price: $10500.00 per piece

CNC Automatic Knife Sharpener Grinding Machine Surface Grinding Machine China Wholesale Factory

Price: $6900.00 per piece

Versatile Veneer Peeling Machine Spindle for Woodworking Applications Import Wholesale

Price: $18000.00 per piece

2 in 1 Spindleless Veneer Peeling Machine - Versatility and Efficiency B2B Wholesale

Price: $18000.00 per piece