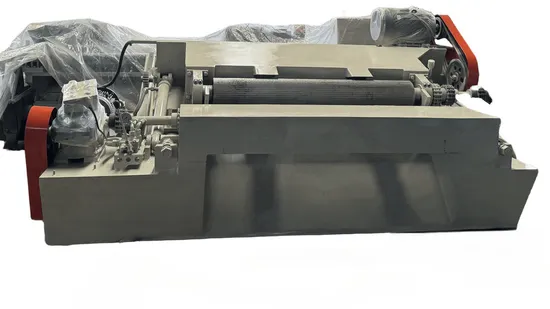

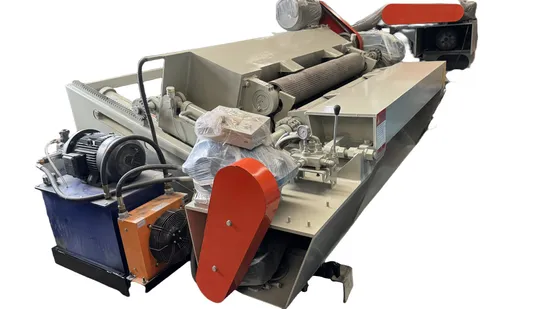

Automated Wood Debarker for Log Decorticating China Factory Direct Production

Category

Machinery

Sub-Category

Woodworking Machinery

Completed orders

0

Price

$8500.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Linyi city, China, Linyi, Shandong, China

| Model NO. | BWZY-L3300-D600 |

| Type | Wood Debarker |

| Automatic | Semi-Automatic |

| Certification | CE |

| Peeling Speed | 45m/Min |

| Customize | Available |

| Knife Blade Size | 2900*140*12.7 mm |

| Wood Log Size | Max. Length 2600 mm |

| Overall Size | 5300*2150*1100 mm |

| Weight | 6000 Kg |

| Transport Package | Plastic Film |

| Specification | 5300*2150*1100 mm |

| Trademark | LINYIZHONGHE |

| Origin | Linyi City, China |

| HS Code | 8465990000 |

| Production Capacity | 15sets/Years |

Company Rating

Overall Rating

Description Rating

Delivery time

Contact

Professionalism

You may like this

Good Reputation Automatic Edge Trim Wood Saw Machine Cross Saw China Industrial Supplier Services

Price: $13000.00 per piece

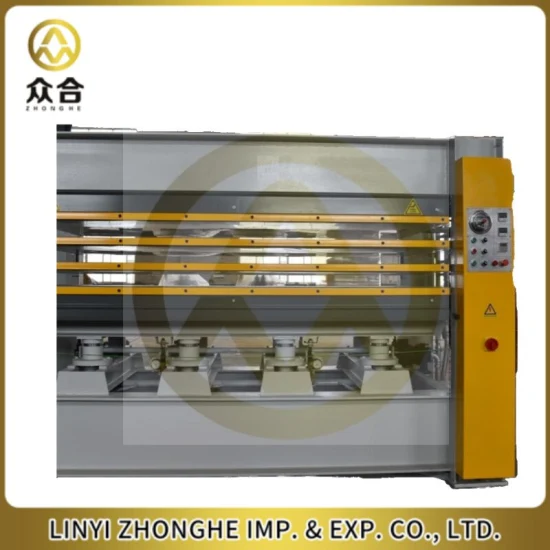

Automatic Film Faced Plywood Hot Pressing Machine Supplier Wholesale Production

Price: $140000.00 per piece

Industrial Wood Debarker Machine for Making Wood Chips Round Logs Mass Production

Price: $9000.00 per piece

Hot Sale Hot Press Machine for Wood Door Bulk Manufacturing

Price: $12500.00 per piece