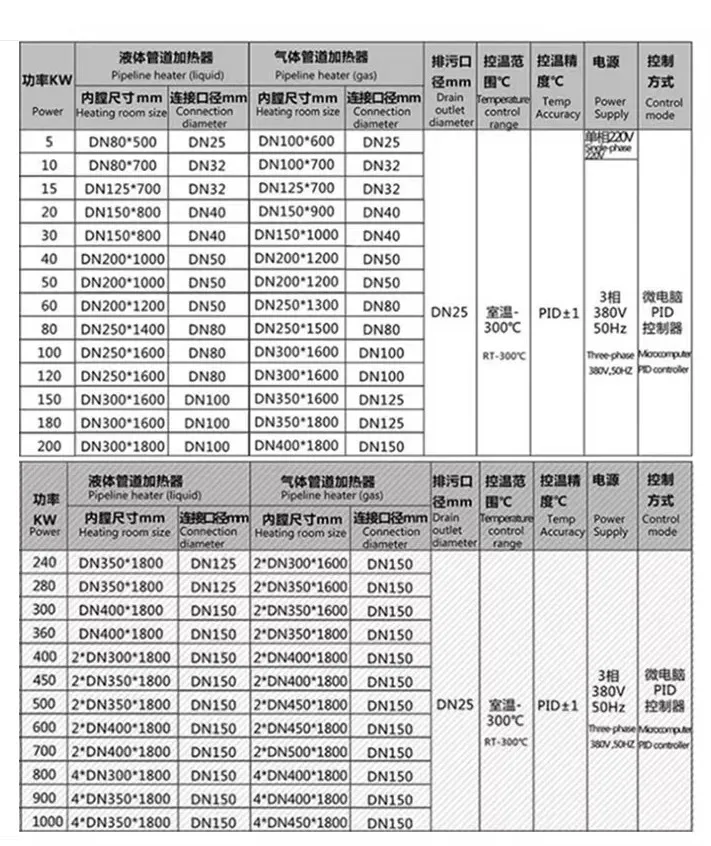

72kw Liquid Oil Pipeline Circulation Process Heater Wholesale B2B Pricing

Category

Electrical Equipment & Supplies

Sub-Category

Refrigeration & Heat Exchange Accessories

Completed orders

0

Price

$1450.00

Delivery Cost

$0.00

Minimum Order

1

pieces

Location

Tongji Road, Gehuang Industrial Concentration Zone, Zhangguo Community, Dainan Town, Xinghua City, TaiZhou, Jiangsu, China

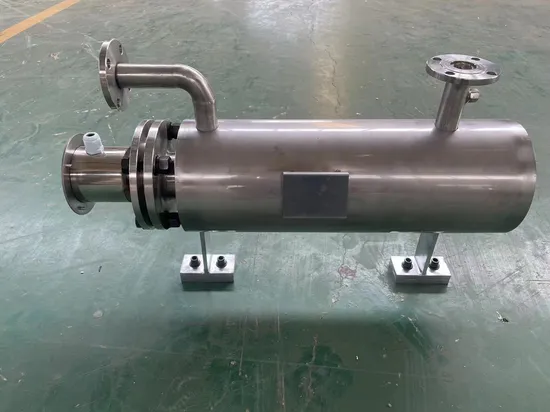

| Material | Stainless Steel |

| Form | Spiral Heating Element |

| Shape | Round |

| Application | Oil, Water |

| Thermal Efficiency | More Than 95% |

| Dimension(L*W*H) | Customized |

| Max Temperature | 800 C |

| Voltage | 220-480V |

| Style | Horizontal Type |

| Transport Package | Wooden Box |

| Specification | can be customized |

| Trademark | Cheri |

| Origin | China |

| HS Code | 8516800000 |

| Production Capacity | 500/Year |

Company Rating